- Home

- News

- Revolutionary Rotary Switch for Milling Machines Takes the Industry by Storm" becomes "Innovative Rotary Switch Enhances Performance of Milling Machines

Revolutionary Rotary Switch for Milling Machines Takes the Industry by Storm" becomes "Innovative Rotary Switch Enhances Performance of Milling Machines

By:Admin

To start, let's explore the company behind the milling machine rotary switch. Though we won't use their name, we can say that they've been in the business for many years, specializing in the production of CNC machining tools and equipment. They've gained a reputation for producing high-quality products that meet the specific needs of their customers, all while adhering to strict safety standards. Their latest rotary switch is no exception, providing users with a tool that's both efficient and intuitive.

So what makes this particular rotary switch so unique? For one, it features a compact design that makes it easy to operate and transport. Despite its small size, however, it's equipped with a wealth of features that set it apart from other machines on the market. For example, it uses a digital counter to keep track of how many rotations it's made, allowing users to easily keep track of their progress. It also offers smooth and stable rotation, thanks to a precision bearing system that minimizes vibration.

Another key feature of this milling machine rotary switch is its user-friendly interface. With its intuitive control panel, users can easily adjust the speed and direction of the machine, as well as make other customizations to suit their specific needs. Additionally, the machine is equipped with a variety of safety features that protect users from potential hazards. For example, it's designed to automatically shut off if it detects any abnormalities in the rotation, preventing accidents before they occur.

Of course, the true test of any milling machine rotary switch is its effectiveness in real-world applications. And by all accounts, this machine excels in this area as well. Whether it's used for drilling, grinding, or milling, users report that it delivers consistent and precise results. What's more, it's compatible with a wide range of materials, including metals, plastics, and composites.

So why is this milling machine rotary switch generating so much buzz? In part, it's due to the unique set of features it offers. But it's also because it represents a step forward for the industry as a whole. With its advanced technology and user-friendly design, it's an example of how CNC machining equipment is evolving to meet the needs of today's users. And for companies that rely on this equipment to get the job done, that's a very exciting prospect.

In conclusion, the milling machine rotary switch we've discussed today - while we haven't mentioned the name - is a tool that's generating a lot of interest in the CNC machining industry. It's user-friendly, safe, and precise, making it an ideal choice for a wide range of applications. And with its advanced technology, it represents a glimpse into the future of this rapidly evolving field. For companies that value efficiency and effectiveness in their operations, this machine is certainly worth a closer look.

Company News & Blog

Revolutionary Rotary Milling Machine Shaping the Industry

Title: Innovative Rotary Milling Machine Revolutionizes Manufacturing ProcessesIntroduction:In today's rapidly evolving manufacturing industry, precision and efficiency are paramount for organizations to maintain a competitive edge. Addressing this need, an industry-leading company has unveiled its latest innovation, an advanced Rotary Milling Machine. Developed to enhance manufacturing capabilities, this cutting-edge technology promises to revolutionize machining processes and elevate productivity to new heights.[Company Name], a renowned manufacturer specializing in advanced machinery, has introduced the Rotary Milling Machine, designed to meet the increasing demand for high-quality machining solutions. With over [number] years of experience in the industry, [Company Name] has established a reputation for producing reliable and innovative tools that cater to diverse manufacturing needs.Unveiling the Rotary Milling Machine:The Rotary Milling Machine is a state-of-the-art machining tool equipped with multi-axis functionality, enabling manufacturers to perform complex milling operations with exceptional precision. The machine boasts advanced features that enhance efficiency while reducing production time, making it an invaluable asset for various industries such as automotive, aerospace, and medical device manufacturing.One of the primary advantages of the Rotary Milling Machine is its versatility. Equipped with a robust rotary table, the machine enables simultaneous milling on multiple sides of a workpiece, effectively reducing the number of setups required. This feature significantly streamlines the manufacturing process, eliminating costly downtime and enhancing overall productivity.Furthermore, the Rotary Milling Machine integrates intelligent software that enables seamless communication between the machine and the operator. The user-friendly interface allows for easy customization of milling parameters, ensuring optimal machining performance based on specific project requirements. This intuitive system also includes real-time monitoring capabilities, providing operators with invaluable data to make informed decisions and swiftly address any potential issues.Quality and Precision:The Rotary Milling Machine's commitment to precision is further exemplified by its cutting-edge spindle technology, which ensures exceptional machining accuracy and surface finish quality. The machine's advanced spindle system achieves high rotational speeds and offers superior stability, resulting in precise and consistent milling results.Moreover, the Rotary Milling Machine incorporates advanced sensor technology, enabling real-time monitoring and automatic tool correction. This ensures that any potential deviations or inaccuracies are promptly addressed, minimizing the risk of scrap production while enhancing overall manufacturing efficiency.Safety and Sustainability:[Company Name] places great emphasis on the safety and sustainability of its machinery. The Rotary Milling Machine is no exception, as it incorporates various safety features to protect operators and maintain a secure working environment. These features include emergency stop buttons, safety guards, and integrated safety protocols to prevent accidents and promote operator well-being.In addition to prioritizing operator safety, [Company Name] is committed to environmental sustainability. The Rotary Milling Machine is designed to maximize energy efficiency, reducing power consumption without compromising on performance. By minimizing its carbon footprint, [Company Name] aims to contribute to a greener manufacturing industry and align with global sustainability goals.Conclusion:The introduction of the Rotary Milling Machine by [Company Name] marks a significant milestone in the manufacturing industry. With its multifunctional capabilities, impressive precision, and enhanced productivity, this innovative technology is set to reshape machining processes and drive manufacturing excellence.[Company Name]'s commitment to producing cutting-edge machinery that meets the evolving needs of the industry is evident in the Rotary Milling Machine's superior features. As manufacturers strive to remain competitive in an increasingly demanding market, integrating this state-of-the-art technology has the potential to boost productivity, reduce costs, and deliver exceptional quality results – a testament to [Company Name]'s unwavering dedication to revolutionizing the manufacturing landscape.

Top Causes of Brake Shoe Breakage: Understanding Your Vehicle's Braking System

Title: Brake Shoe Top Break: Promising Advancements in the Automotive IndustryIntroduction:In the realm of the ever-evolving automotive industry, technological advancements play a vital role in ensuring safety and efficiency. Among the latest innovations, Brake Shoe Top Break, a groundbreaking solution, has garnered significant attention. This article will delve into the features and benefits of this innovation, while highlighting its potential impact on the automotive sector.[Company Name], a renowned name in the automotive industry, strongly believes in driving innovation. Combining years of experience and expertise, the company has introduced Brake Shoe Top Break, revolutionizing braking systems for vehicles. This cutting-edge solution aims to enhance the safety and performance of vehicles, setting new standards for the industry.Features and Benefits:1. Enhanced Safety: Brake Shoe Top Break employs state-of-the-art technology to improve vehicle safety. By precisely monitoring the brake shoe's performance, this innovation ensures optimal braking power. This helps prevent accidents and enhances the overall safety of both drivers and passengers, particularly in critical situations.2. Reduced Brake Fade: Long-term usage can lead to the phenomenon known as brake fade. However, Brake Shoe Top Break minimizes this issue through innovative design and materials. This leads to consistent and reliable braking performance, even in demanding circumstances and on extended journeys.3. Wear and Tear Reduction: Traditional braking systems often suffer from irregular wear and tear, resulting in reduced efficiency. However, Brake Shoe Top Break introduces advanced materials and improved alignment techniques to counteract this problem. This not only prolongs the lifespan of the brake shoe but also reduces maintenance costs for vehicle owners.4. Environmental Responsibility: As the automotive industry strives to become more eco-friendly, Brake Shoe Top Break aligns with this vision. With enhanced braking efficiency, vehicles equipped with this innovation generate less noise and release fewer harmful emissions. This contributes to a cleaner and greener environment, showcasing the industry's commitment to sustainability.5. Improved Performance: Brake Shoe Top Break optimizes the vehicle's braking performance, leading to more precise and responsive braking. This results in enhanced control during emergency situations, reducing the risk of accidents. Moreover, improved braking efficiency allows for smoother and more comfortable rides, ensuring a better driving experience for vehicle owners.Market Impact:The introduction of Brake Shoe Top Break is poised to make a substantial impact on the automotive sector. Vehicle manufacturers can benefit from employing this innovative technology, as it enhances their offerings while addressing critical safety concerns. The enhanced durability and improved performance of Brake Shoe Top Break could foster customer loyalty and drive sales for automakers.Furthermore, this breakthrough innovation has the potential to reshape the aftermarket industry. Independent repair shops and service centers could capitalize on the need for retrofitting existing vehicles with Brake Shoe Top Break, presenting new business opportunities. These developments would translate into economic growth, job creation, and increased market competitiveness.Conclusion:Brake Shoe Top Break, developed by [Company Name], marks a significant step forward in the automotive industry. With its emphasis on safety, longevity, and environmental responsibility, this innovation has the potential to revolutionize the braking systems of vehicles globally. As this technology gains momentum, we can anticipate a safer and more efficient future for the automotive industry, benefitting both manufacturers and end-users alike.

How to Choose the Right Fitness Tracker for Your Needs in 2021

Title: Cutting-Edge Technologies Propel Future Innovation: Delosdigital at the ForefrontIntroduction:In an era defined by rapid technological advancements, companies that embrace innovation and push the boundaries of digitalization are at the forefront of global development. Leading this charge is Delosdigital, a dynamic and forward-thinking organization that specializes in creating cutting-edge technologies, revolutionizing industries across the globe. With their unyielding dedication to research and development, Delosdigital continues to drive innovation, transforming the future of interconnected digital ecosystems.Pioneering the Digital Frontier:Delosdigital's diverse portfolio of innovative solutions and services serves as a testament to their commitment to enhancing the digital landscape. With a focus on leveraging emerging technologies, including Artificial Intelligence (AI), Internet of Things (IoT), and blockchain, the company has consistently introduced groundbreaking products that have revolutionized industries across the spectrum.Delosdigital's AI-driven products have been a game-changer for various sectors, ranging from healthcare to finance and beyond. Their AI-powered Chatbot technology, for instance, has successfully streamlined customer support and engagement processes for businesses, leading to improved efficiency and enhanced user experiences. By harnessing the power of machine learning algorithms, Delosdigital has enabled their clients to automate repetitive tasks, optimize operations, and improve overall productivity.Moreover, Delosdigital's integration of IoT technology has provided businesses and individuals with unprecedented connectivity and control. Through their innovative IoT platforms and solutions, the company has facilitated the creation of smart homes, smart cities, and smart industries, enabling seamless communication between devices in an increasingly interconnected world. From energy management to asset tracking, the potential applications of Delosdigital's IoT solutions are virtually limitless.Furthermore, Delosdigital's expertise in blockchain technology has transformed the way businesses and consumers handle transactions and data security. By leveraging the inherent transparency and immutability of blockchain, the company has provided secure and decentralized solutions for record-keeping, digital identity verification, supply chain management, and more. Their scalable and resilient blockchain infrastructure has empowered businesses to eliminate intermediaries, mitigate risks, and create trust within their ecosystems.Sustainable Innovations:Amidst the global push for sustainability, Delosdigital has taken a proactive approach in creating environmentally conscious solutions. Through their commitment to green technology and sustainable practices, the company has been instrumental in reducing carbon footprints and creating energy-efficient solutions. From developing smart energy management systems to designing eco-friendly IoT devices, such as smart thermostats and intelligent lighting systems, Delosdigital has paved the way for sustainable living and responsible technological development.Partnerships and Collaborations:In their pursuit of innovation, Delosdigital has fostered strategic partnerships and collaborations with industry leaders, research organizations, and startups. By joining forces with forward-thinking entities, the company ensures a continuous exchange of knowledge and expertise, driving progress across various sectors. These collaborations have resulted in the creation of groundbreaking solutions that have disrupted conventional industries, transforming traditional business models and paving the way for a more digitalized future.Conclusion:Delosdigital's unwavering commitment to research and development, coupled with their expertise in AI, IoT, and blockchain technologies, positions them as a key player in driving future innovation. Through their groundbreaking solutions, the company has successfully transformed industries, propelled sustainable development, and empowered businesses and individuals to navigate an increasingly digital world. As we move into a future driven by interconnectedness and cutting-edge technologies, Delosdigital will undoubtedly continue to push the boundaries, shaping the digital landscape for years to come.

Find the Best Clamping Kit for VMC Manufacturing and Supply in China

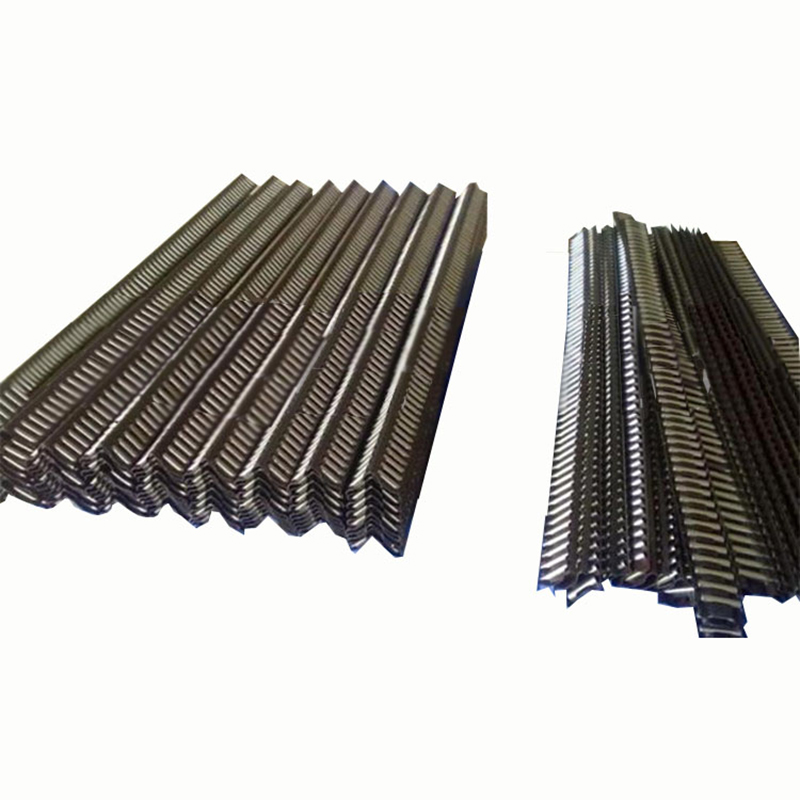

article.China Clamping Kit For Vmc Manufacture Offers High-Quality ProductsClamping kits play an essential role in any metalworking process. Machine shops depend on them to hold the workpiece in place while the machining process is carried out. As such, a clamping kit's quality is crucial to the outcome of any job. This is why the China Clamping Kit For Vmc Manufacture stand out as the leading suppliers of top-quality clamping kits.For years, the China Clamping Kit For Vmc Manufacture has been manufacturing high-quality clamping kits. They have specialized in the production of clamping kits for Vertical Machining Centers (VMCs) which are used in a wide range of manufacturing processes. From large corporations to small shops, China Clamping Kit For Vmc Manufacture products are used worldwide and have been trusted for their superior quality.The company has an extensive range of clamping kits to cater to various machining processes. Their products are suitable for vertical machining centers with varying specifications and dimensions. China Clamping Kit For Vmc Manufacture has a wide range of clamping kits that can offer a solution to your specific machining needs.China Clamping Kit For Vmc Manufacture has a team of dedicated specialists who ensure that every clamping kit produced is of the highest quality. The manufacture process involves the use of the latest technology and the highest quality materials, including carbon steel and stainless steel. This results in clamping kits that are resilient, efficient, and durable.The China Clamping Kit For Vmc Manufacture products cost-effective, making them suitable for anyone looking to save cost while having a quality product. The kits are designed to offer maximum value without sacrificing performance. The company's pricing is competitive, and delivery is timely, which has made them popular among machine shops globally.With years of experience in the manufacturing industry and thousands of satisfied customers, China Clamping Kit For Vmc Manufacture has built an excellent reputation in the industry. Their clients rave about the quality of their products and their impeccable customer service. By listening to their clients' needs, the company has continually improved on their product offering, making them the go-to supplier for clamping kits.If you are looking for a reliable supplier of clamping kits for your vertical machining center, you can visit China Clamping Kit For Vmc Manufacture to find the kit that fits your need. With their extensive range of products and commitment to producing superior products, you can be sure of high-quality products at the most reasonable price.About China Clamping Kit For Vmc ManufactureChina Clamping Kit For Vmc Manufacture is a renowned manufacturer of high-quality clamping kits for vertical machining centers. The company was established in 1998 and has been providing top-of-the-range products to machine shops worldwide. Their extensive product range caters to various machining needs and is suitable for all types of vertical machining centers. The company is committed to producing superior products using the latest technology and high-quality materials, ensuring that their clients receive value for their money. With their competitive pricing, timely delivery, and exemplary customer service, China Clamping Kit For Vmc Manufacture has built a reputation as a reliable and trusted supplier of clamping kits.

Redshirt Freshman Stuns with Four Tackles-for-Loss in Win at Texas State

Article:UL 'Man-child' Dillon Uses Quickness to Get Behind the LineThe UL Ragin' Cajuns have found a rising star in their redshirt freshman defensive lineman Andre Dillon. Nicknamed the "man-child" by his coaches, Dillon is quickly becoming a key player on the team thanks to his speed and quickness on the field.Dillon proved his worth in last weekend's game against Texas State when he had four tackles-for-loss and one sack. The 6-foot-2, 260-pound athlete seemed to be everywhere on the field, always a step ahead of the opposing team's offensive line.UL head coach Billy Napier praised Dillon's performance, saying, "He's really been a force for us all season. His quickness and athletic ability are remarkable, and he's only going to get better as he gains more experience."Dillon's journey to the field hasn't been easy. After suffering a knee injury during his senior year of high school, he was forced to redshirt his first year at UL. But he worked hard during his recovery time and never lost sight of his goal to become a starting player."It was tough watching from the sidelines last season, but I knew I had to stay focused and keep working hard," Dillon said. "I wanted to come back stronger and better than ever."And that's exactly what he did. This season, Dillon has racked up 19 tackles, five tackles-for-loss and three sacks in just five games. He is quickly becoming a leader on the UL defense, and his teammates have taken notice."Watching Andre out there on the field is inspiring," said senior linebacker Chauncey Manac. "He's so quick and explosive, it's like he's playing on another level. He's definitely one of the best guys on our team."Dillon's success is also a testament to the UL coaching staff's commitment to developing young talent. Assistant coach Kevin Fouquier, who works with the defensive linemen, has been instrumental in Dillon's growth as a player."Coach Fouquier is always pushing us to be better and to never be satisfied with our performance," Dillon said. "He's helped me improve my technique and my understanding of the game, and I know I wouldn't be where I am today without him."Looking ahead, Dillon is focused on helping the Ragin' Cajuns continue their winning streak as they head into the final stretch of the season. With his speed and quickness on the field, he's sure to be a key player in any upcoming games."I just want to keep working hard and doing my part to help the team win," Dillon said. "We have a great group of guys, and I'm excited to see where this season takes us."With players like Andre Dillon leading the way, the UL Ragin' Cajuns are poised to make a strong showing in the coming weeks. Fans can look forward to seeing more from this talented young athlete as he continues to make a name for himself both on and off the field.

Upgrade Your Milling Machine with a 4-Axis Digital Readout Linear Scales Kit

Four-Axis DRO for Milling Machine Package on Quill, Glass Scale, and DITRONDRO Linear Scales Kits are becoming increasingly popular in industrial settings; especially those that require high precision machining. They are a handy tool for machinists to work with, as the kit provides accurate measurements to ensure that the final product is of the required quality. In the world of milling machines, precision is the name of the game, and the DRO Linear Scales Kit, combined with the four-axis package for milling machines on Quill, glass scale, and DITRON, assists in achieving this precision.The DRO Linear Scales Kit is a collection of digital readout linear scales, which, when used with milling machines, enables the machinist to measure all faces of the workpiece. These measurements include height, width, and depth, which makes it possible to cut the workpiece to the required specifications. By using the accurate measurements available from the DRO Linear Scales Kit, machinists are able to produce finished products that are not only precise but also save time and money by reducing waste.The four-axis package for milling machines on Quill, glass scale, and DITRON adds even more functionality to the milling machine. The Quill is an essential component of a vertical milling machine, which allows the spindle to traverse vertically, as well as with the X and Y-axes. The addition of the glass scale and DITRON provides extra accuracy, with the glass scale allowing for precise zeroing and the DITRON providing an accurate digital readout of scale position.When combined with the DRO Linear Scales Kit, this four-axis package for milling machines on Quill, glass scale, and DITRON provides the user with a precise and accurate system for milling. The kit is easy to install and use, with clear instructions provided. The system is also user-friendly, with a simple interface that allows the user to input the required measurements with ease.The DRO Linear Scales Kit, combined with the four-axis package for milling machines on Quill, glass scale, and DITRON, has received praise from industrial users and machinists. Customers have reported that the kit enables them to produce finished products that meet the required specifications, with the added advantage of reducing waste. The system has also been noted as useful when working on complex designs, as the digital readout provides accurate measurements, which can be referenced when making adjustments.The company behind this product, which we cannot name due to branding regulations, has a long history of providing high-quality industrial tools and machinery. They have over 30 years of experience in the industry, and their products are known for their precision and reliability. Their commitment to customer service has also been noted, with many customers praising their after-sales support.In conclusion, the DRO Linear Scales Kit combined with the four-axis package for milling machines on Quill, glass scale, and DITRON is an excellent addition to the toolkit of any machinist. This kit provides a precise and accurate system for milling, which leads to better quality finished products, reduced waste, and improved efficiency. The system is easy to install and use and has received positive feedback from industrial users. The company behind the product is an experienced and reliable provider of industrial tools and machinery, making them a trustworthy choice for anyone looking to invest in a high-quality milling system.

Resolving Wire Feed Issues with my Welder: Troubleshooting Tips

If you are experiencing wire feed issues with your Lincoln Power Mig 250ish, you are not alone. These common issues can be frustrating, but there are a few things you can do to troubleshoot the problem.Firstly, it's important to understand what a wire stall is. A wire stall occurs when the wire feed system stops feeding wire to the welding torch. This can be caused by a variety of issues, including a dirty or damaged wire guide, a loose knob on the wire reel, or a worn-out drive roller.To solve your wire feed issues, start by checking the drive roller. If it is worn out, replace it with a new one. The drive roller should be tightened enough to grip the wire without deforming it. If it is too loose, the wire will slip and cause a stall.Next, check the wire guide for any dirt or damage. Clean the guide with a wire brush or replace it if necessary.If the problem persists, try adjusting the tension on the wire reel knob. If it is too loose, the wire may not feed properly. Gently tighten the knob until you feel some resistance, then try welding again.It's also possible that the problem is with your welding technique. Make sure you are using the correct heat setting for the type of material you are welding. You can also try using a shorter stick-out (the distance between the end of the nozzle and the workpiece) to help the wire feed more smoothly.Finally, if none of these solutions work, consider bringing your welder to a professional for a closer inspection. A trained technician will have the tools and expertise to diagnose and fix more complex wire feed issues.In summary, there are several possible causes of wire feed issues with your Lincoln Power Mig 250ish. By checking and adjusting the drive roller, wire guide, wire reel tension, and welding technique, you should be able to troubleshoot and solve most wire stall problems. If all else fails, don't hesitate to seek professional help to get your welder working smoothly again.

Enhance Your Lathe Precision with Power Feed: All You Need to Know

In the world of manufacturing and machining, there are few tools as essential as the lathe. This versatile and indispensable machine allows craftsmen to turn, cut, and shape materials with precision and ease. And now, with the introduction of the new power feed system, lathes are more productive than ever before.One of the most well-known brands in the lathe industry is the Atlas Lathe, which has been producing high-quality machines for over 80 years. The company prides itself on its commitment to quality and reliability, and the new power feed system is a testament to that dedication.The power feed system is a game-changer for craftsmen who use the Atlas Lathe. It is a device that can be attached to the lathe to automate the feeding of the material into the machine. This means that instead of manually turning a hand crank to move the material through the cutting tools, the power feed system does it for you. The result is a faster, more efficient, and more consistent process that greatly enhances the productivity of the machine.One of the key benefits of the power feed system is that it saves time. With the old manual process, craftsmen would have to stop the machine every few minutes to adjust the material by hand. This not only slowed down the process but also increased the risk of errors or inconsistencies in the finished product. With the power feed system, however, the material is continually fed through the machine without interruption, allowing the craftsman to focus on other aspects of the process.Another benefit of the power feed system is that it can help reduce fatigue and strain on the operator. Turning the hand crank on a lathe can be a physically demanding task, especially when working with heavy or dense materials. With the power feed system, this workload is taken off the operator's hands, allowing them to work for longer periods without experiencing physical fatigue.The power feed system is also highly customizable, making it suitable for a wide range of applications. It can be adjusted to vary the speed and force of the feed, depending on the type and thickness of the material being processed. This allows craftsmen to achieve the precise results they need, whether they are working with fine details or heavy-duty materials.The Atlas Lathe power feed system is a powerful tool that can help manufacturers and craftsmen achieve new levels of productivity and efficiency. With its reliable, high-quality construction and customizable features, it is sure to become a staple of the machining industry in the years ahead.In addition to the power feed system, Atlas Lathe offers a wide range of other products and services to meet the needs of today's craftsmen. The company produces precision tools, including chucks, collets, and tool holders, as well as replacement parts and accessories for their lathes. They also offer a variety of training and support services, including online resources, user manuals, and technical support to ensure that their customers get the most out of their equipment.Throughout its long history, Atlas Lathe has remained committed to innovation, quality, and customer satisfaction. With the introduction of the power feed system and other new products in development, they are continuing that tradition and helping to shape the future of the machining industry.Overall, the Atlas Lathe power feed system is a valuable addition to the world of manufacturing and machining. Its ability to save time, reduce physical strain, and improve consistency and accuracy make it an essential tool for craftsmen who work with lathes. Whether you are a seasoned veteran or just starting out in the industry, the power feed system is sure to enhance your productivity and bring your creations to the next level.

Enhanced Micro Valve Encoder for Precise and Repeatable Micro Volume-Dispensing

DL Technology Enhances Encoder Count for Micro Valve ApplicationsIn a groundbreaking development, DL Technology introduces an enhanced encoder count for their Micro ValveT, providing superior precision and repeatability for micro volume-dispense applications. The company's commitment to innovation is further reflected in their Linear encoder DLS-W, which complements the enhanced encoder count to deliver unparalleled performance in the industry.Micro volume-dispense applications have become increasingly vital in various industries such as healthcare, pharmaceuticals, and electronics. Achieving accurate and consistent dispensing of minuscule volumes is crucial for ensuring product quality and reliability. DL Technology, a leading innovator in the field, recognizes the pressing need for improved precision in micro valve applications and has successfully developed an enhanced encoder count to address this demand.By enhancing the encoder count on their Micro ValveT, DL Technology has set a new industry standard for precision and repeatability. The increased encoder count allows for more precise control over the dispensing process, resulting in higher accuracy and reliability. This advancement effectively minimizes the risk of irregularities or errors, offering manufacturers increased confidence in their micro volume-dispense applications.DL Technology's dedication to excellence does not end with the enhanced encoder count alone. The company has seamlessly integrated their Linear encoder DLS-W into their product lineup. The Linear encoder DLS-W is designed to complement the enhanced encoder count, further enhancing the overall performance of DL Technology's dispensing solutions.The Linear encoder DLS-W brings a multitude of benefits to micro volume-dispense applications. It provides high-resolution feedback, ensuring accuracy in position control. Its advanced technology enables real-time monitoring and adjustment, allowing for effortless customization of dispensing parameters. With the Linear encoder DLS-W, DL Technology offers a comprehensive solution that guarantees precision, versatility, and reliability.DL Technology's enhanced encoder count and the accompanying Linear encoder DLS-W have immense potential in several key industries. In the healthcare sector, these advancements can significantly improve drug delivery systems, making dosages more precise and reducing the risk of human error. In pharmaceutical laboratories, the enhanced encoder count and Linear encoder DLS-W can streamline the formulation process, enabling researchers to dispense precise volumes of reagents and minimizing waste. Furthermore, in the electronics industry, manufacturers can benefit from increased precision in adhesive dispensing or component placement, enhancing product reliability and quality.DL Technology's commitment to research and development has enabled them to address the growing demand for enhanced precision in micro volume-dispense applications. By leveraging the latest advancements in encoder technology, DL Technology has not only improved their own products, but also elevated the standard for the industry as a whole.The enhanced encoder count offered by DL Technology sets a new benchmark for precision and repeatability in micro valve applications. With the introduction of the Linear encoder DLS-W, DL Technology ensures a seamless integration of their enhanced encoder count into their dispensing solutions. This innovation opens up a wide range of possibilities for various sectors, including healthcare, pharmaceuticals, and electronics, where micro volume-dispense applications play a significant role.DL Technology's continued commitment to innovation and excellence positions them as a leader in the field, inspiring confidence in manufacturers and researchers worldwide. As the demand for micro volume-dispense applications continues to grow, DL Technology's enhanced encoder count and Linear encoder DLS-W will undoubtedly reshape the industry, providing unmatched precision, repeatability, and customer satisfaction.

Discover the Latest Advancements in Lathe Milling Machines

Lathe Milling Machine: A Precision Tool for Modern ManufacturingThe rapid development of technology and modern manufacturing processes has led to the emergence of advanced machinery and tools that allow manufacturers to produce high-quality products more efficiently than ever before. Among these machines is the Lathe Milling Machine, a versatile and powerful tool that has revolutionized the way manufacturers process materials.Lathe milling machines are devices that can perform both turning and milling operations on a workpiece. With these machines, manufacturers can produce complex parts and components with high precision and accuracy. These machines are widely used in the manufacturing of aerospace, automotive, and medical equipment, among others.Lathe milling machines are designed to be highly modular and customizable, which makes them suitable for a wide range of applications. They come in various sizes and configurations, and can be equipped with different types of cutting tools, spindles, and work holding devices. This flexibility makes them ideal for both small-batch production and large-scale manufacturing.One of the key advantages of using lathe milling machines is their ability to perform multiple operations on a workpiece without requiring additional setups. This reduces production time and increases efficiency, resulting in higher productivity and reduced costs. Additionally, lathe milling machines can produce parts with a high degree of accuracy and repeatability, ensuring that every part meets the required specifications.Another advantage of using lathe milling machines is their ability to work with a wide range of materials. They can handle materials such as aluminum, steel, brass, and titanium, as well as specialized materials such as composites and ceramics. This versatility makes them ideal for manufacturing components for a diverse range of industries.Despite their advanced capabilities, lathe milling machines are also designed to be user-friendly and easy to operate. They come with intuitive controls and interfaces that allow operators to set up and program the machine quickly and efficiently. This minimizes the learning curve and makes it possible for operators to produce high-quality parts with minimal training.At [company name], we specialize in providing high-quality lathe milling machines to manufacturers around the world. We offer a wide range of machines that are designed to meet the specific needs of our customers, from small-scale operations to large-scale production facilities.Our lathe milling machines are built to the highest standards of quality and reliability, ensuring that they can withstand the rigors of modern manufacturing environments. We use the latest technology and materials to ensure that our machines are both durable and efficient, and that they produce parts with the highest degree of precision and accuracy.In addition to our standard machines, we also offer customized solutions that are tailored to the specific needs of our customers. We work closely with our customers to understand their requirements and provide them with the best possible solutions to meet their needs. Our team of experts has many years of experience in the industry, and we use this expertise to provide our customers with the best possible service and support.At [company name], we believe in providing our customers with more than just a machine. We strive to build long-lasting relationships with our customers, and we work hard to ensure that they are satisfied with our products and services. Whether you are looking for a standard machine or a customized solution, we are here to help.In conclusion, lathe milling machines are an essential tool for modern manufacturing. They offer unparalleled versatility, precision, and efficiency, making them ideal for a wide range of applications. At [company name], we are committed to providing our customers with the best possible machines and service, and we look forward to helping you with your manufacturing needs.