Enhance Your Mill with a Powerful Servo Power Feed

By:Admin

The company behind Servo Mill Power Feed is committed to delivering high-quality solutions to meet the evolving needs of the industrial sector. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted provider of cutting-edge equipment for a wide range of applications. The success of Servo Mill Power Feed is a testament to the company’s dedication to excellence and its ability to deliver products that exceed industry standards.

One of the key features of Servo Mill Power Feed is its precision control capabilities, which allow operators to achieve consistent and accurate results with every use. This level of control is crucial in milling and drilling operations, where even the slightest deviation can lead to costly errors and rework. With Servo Mill Power Feed, users can set the desired feed rate with ease and confidence, knowing that the equipment will deliver the exact performance required for the task at hand.

In addition to its precision control, Servo Mill Power Feed also offers exceptional durability and reliability, making it a valuable investment for any industrial setting. The product is designed to withstand the rigors of heavy-duty use, ensuring consistent performance and longevity even in the most demanding work environments. This level of durability is a hallmark of the company’s commitment to quality, as it continues to set the standard for industrial machinery and equipment.

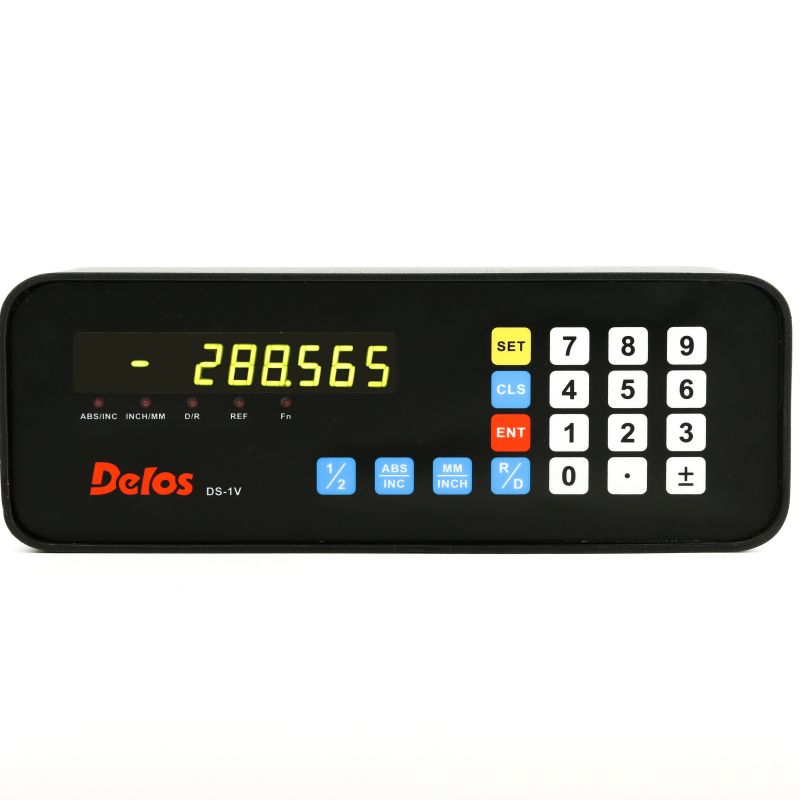

Another standout feature of Servo Mill Power Feed is its user-friendly design, which allows operators to quickly and effectively integrate the equipment into their existing workflow. The product’s intuitive interface and straightforward controls make it easy for personnel to master its operation, reducing the need for extensive training and minimizing the potential for errors. This user-friendly approach is a testament to the company’s dedication to creating products that are not only advanced but also accessible to a wide range of users.

Servo Mill Power Feed is also backed by a comprehensive support network, ensuring that users have access to expert guidance and assistance whenever necessary. The company’s commitment to customer service extends beyond the initial purchase, with a team of knowledgeable professionals available to address any questions or concerns that may arise. This level of support further demonstrates the company’s focus on delivering complete solutions and ensuring the long-term satisfaction of its clients.

As industry demands continue to evolve, Servo Mill Power Feed remains at the forefront of innovation, with ongoing research and development efforts aimed at enhancing its capabilities and expanding its potential applications. The company’s investment in advancing the technology behind Servo Mill Power Feed reflects its ongoing commitment to pushing the boundaries of what is possible in the industrial sector. This dedication to progress ensures that the product will continue to meet the ever-changing needs of modern manufacturing and metalworking operations.

In conclusion, Servo Mill Power Feed is a groundbreaking product from a leading manufacturer of industrial machinery and equipment, representing the culmination of years of research and development. With its precision control, durability, user-friendly design, and comprehensive support network, Servo Mill Power Feed has set a new standard for performance in industrial milling and drilling operations. The product’s success is a testament to the company’s unwavering commitment to excellence and its ability to deliver advanced solutions that meet the evolving needs of the industrial sector.

Company News & Blog

Discover the Ultimate Milling Accessories for Optimum Performance

Title: Introducing Innovative Milling Accessories: C70 and C71 Revolutionize the IndustryIntroduction:In a constant pursuit to enhance operational efficiency and improve productivity, milling industry leader [Company Name] has launched two ground-breaking milling accessories, C70 and C71. Promising to revolutionize the field, these innovative accessories are designed to elevate milling performance to unprecedented levels, leading to a paradigm shift in the industry. With advanced technology and exceptional craftsmanship, the C70 and C71 are set to redefine milling processes, cementing [Company Name]'s position as an industry frontrunner.Milling Revolution: C70The C70 milling accessory boasts an array of cutting-edge features that ensure superior performance in milling operations. Precision-engineered with efficiency in mind, the C70 is equipped with state-of-the-art components that allow for optimal material removal rates, resulting in significant time savings. The accessory's streamlined design and exemplary balance guarantee straight, accurate cuts, thus reducing the need for additional finishing processes.Equipped with high-quality diamond-coated inserts, the C70 ensures exceptional durability and extended tool life. Its unique coating enhances resistance against wear, minimizing the need for frequent tool changes. This aspect significantly reduces downtime, saving valuable resources and ultimately increasing operational efficiency.Moreover, the C70's innovative chip breaker design enables efficient chip control, preventing chip accumulation and enhancing chip evacuation. This advancement not only improves overall milling quality but also reduces the occurrence of production-related errors, further lowering costs and enhancing milling outcomes.Revolutionized Performance: C71Complementing the C70 is the C71, another groundbreaking milling accessory that elevates performance and efficiency. Engineered to address specific milling challenges, the C71 offers unique advantages over conventional accessories. Equipped with a specially designed flute profile, the C71 minimizes vibrations and significantly reduces cutting forces. This feature ensures enhanced precision during the milling process, resulting in improved surface finish.The C71's optimized geometry and advanced material composition exhibit superior heat resistance. This groundbreaking characteristic allows the accessory to withstand even the most demanding milling operations without compromising on performance. The C71 is designed to handle various materials, including hardened steels, stainless steels, and high-temperature alloys, expanding the versatility of milling processes.Furthermore, the C71 is compatible with a wide range of machining centers, making it accessible to a broader range of milling professionals. Combining this accessibility with its exceptional performance characteristics, [Company Name] aims to democratize high-quality milling processes and equip professionals across the globe with the tools they need to excel in their respective fields.Conclusion:With the launch of the C70 and C71 milling accessories, [Company Name] has set a new standard for excellence in the milling industry. These advanced tools introduce a range of cutting-edge features, revolutionizing efficiency, precision, and durability in milling operations. By combining innovative design, exceptional craftsmanship, and advanced technology, [Company Name] continues to shape the future of milling, pushing the boundaries of what is possible in the field. As the industry progresses towards ever-increasing demands, the C70 and C71 are poised to accompany professionals on their journey towards superior milling performance.

A Guide to Choosing the Best Milling Head for Your Lathe

[Company Name], a leading supplier of industrial machinery, has recently introduced a new milling head for lathes. This innovative product is designed to enhance the capabilities of lathes, allowing for more precise and efficient machining operations.The new milling head is a testament to [Company Name]'s commitment to continuous innovation and providing cutting-edge solutions to its customers in the manufacturing industry. With over [number] years of experience in the field, the company has established itself as a reliable partner for businesses looking to improve their machining processes.The milling head for lathes is designed to be easily adjustable and compatible with a wide range of lathe models. This versatility allows manufacturers to upgrade their existing equipment without the need for a complete overhaul of their machining infrastructure. This cost-effective solution is expected to appeal to companies looking to improve their productivity without making a significant investment in new machinery.One of the key features of the new milling head is its high-speed spindle, which enables faster cutting speeds and improved surface finish. This is particularly beneficial for businesses working with difficult-to-machine materials or tight production deadlines. Additionally, the milling head is equipped with advanced cooling and chip evacuation systems to ensure smooth and efficient machining operations.In addition to its technical capabilities, the milling head for lathes is designed with user-friendliness in mind. The ergonomic design and intuitive controls make it easy for machinists to set up and operate the equipment, reducing the risk of human error and increasing overall efficiency in the production process.[Company Name] has a strong focus on customer satisfaction, and the introduction of the milling head for lathes is a response to the specific needs and challenges faced by manufacturers in the industry. By collaborating closely with customers and understanding their unique requirements, the company is able to develop tailor-made solutions that address their pain points and improve their overall operations."We are excited to introduce the new milling head for lathes, which represents a significant advancement in our product offering," said [Key Company Spokesperson]. "We believe that this product will provide our customers with a competitive edge in their machining operations, allowing them to achieve higher levels of precision and productivity."As part of its commitment to delivering comprehensive solutions, [Company Name] also offers technical support and training for its products. This ensures that customers are able to maximize the potential of the milling head for lathes and integrate it seamlessly into their existing workflows.The introduction of the milling head for lathes is part of [Company Name]'s long-term vision to be a leader in the industrial machinery sector. By investing in research and development, the company aims to stay ahead of the curve and anticipate the evolving needs of its customers in an ever-changing industry landscape.In conclusion, the new milling head for lathes from [Company Name] is set to revolutionize the way manufacturers approach their machining operations. With its advanced technology, user-friendly design, and focus on customer satisfaction, this product is poised to make a significant impact in the industry. As [Company Name] continues to push the boundaries of innovation, it is undoubtedly a company to watch in the industrial machinery sector.

How Industrial Digital Scales are Revolutionizing the Weighing Industry

Today, Industrial Digital Scale, a leading provider of industrial weighing solutions, announced the release of a new line of digital scales designed to meet the growing demand for accurate and reliable weighing in industrial settings. The company, with over 20 years of experience in the industry, has a strong reputation for producing high-quality weighing equipment that meets the needs of various industries, including manufacturing, logistics, and food processing.The new line of digital scales features advanced technology and innovative design, making them the ideal choice for businesses looking to improve efficiency and accuracy in their weighing processes. With a focus on precision and durability, Industrial Digital Scale's new products are designed to withstand the rigors of industrial environments while providing consistently accurate measurements."Accuracy and reliability are crucial in industrial weighing applications, where even the slightest error can have significant consequences," said the spokesperson for Industrial Digital Scale. "With our new line of digital scales, we are committed to providing our customers with the tools they need to ensure precise weighing results, ultimately improving their operational efficiency and product quality."One of the key features of the new digital scales is their advanced digital display, which provides clear and easy-to-read measurements, even in low-light conditions. This feature is particularly useful in industrial settings where visibility may be limited, ensuring that operators can accurately read the weight of their materials or products at all times.In addition to their advanced display, the new digital scales also come equipped with a range of connectivity options, allowing for seamless integration with existing industrial systems and processes. This connectivity enables businesses to streamline their weighing operations, improve data accuracy, and enhance overall productivity.Furthermore, Industrial Digital Scale has incorporated industry-leading weighing technology into its new line of digital scales, ensuring that users can rely on precise and consistent measurements. With features such as load cell technology and advanced weighing algorithms, the new digital scales can accurately weigh even the most challenging materials and products, providing peace of mind to operators and managers alike.As a company, Industrial Digital Scale has always been at the forefront of innovation in the weighing industry. With a team of experienced engineers and technicians, the company continuously strives to develop cutting-edge solutions that address the evolving needs of its customers. By leveraging the latest advancements in weighing technology, Industrial Digital Scale aims to empower businesses to optimize their weighing processes and achieve new levels of efficiency and accuracy."We are dedicated to providing our customers with the best possible weighing solutions, and our new line of digital scales is a testament to that commitment," said the spokesperson. "We believe that these new products will make a significant impact on the way businesses approach weighing in industrial settings, ultimately driving better outcomes and greater success for our clients."In conclusion, Industrial Digital Scale's new line of digital scales represents a significant advancement in the industrial weighing industry, offering businesses a reliable and accurate solution for their weighing needs. With a focus on precision, durability, and connectivity, these new digital scales are poised to revolutionize the way businesses approach weighing in industrial settings, setting a new standard for performance and reliability.

New Cross Feed Technology Revolutionizes Power Generation

Power Cross Feed Technology Revolutionizes Machinery IndustryIn today's rapidly evolving machinery industry, the demand for innovative and efficient technology is at an all-time high. That's why companies like [Company Name], a leading manufacturer in the industry, are constantly striving to develop cutting-edge solutions to meet the needs of their customers. With the introduction of their latest technology, Power Cross Feed, [Company Name] is once again setting a new standard for performance and productivity in the machinery industry.The Power Cross Feed is a revolutionary technology that has the potential to greatly enhance the efficiency and precision of machinery operations. By providing a seamless and precise feed motion in the X and Y axes, this technology offers a level of control and accuracy that was previously unattainable. With the Power Cross Feed, operators can now achieve higher levels of productivity while maintaining a superior level of quality in their work.One of the key features of the Power Cross Feed is its ability to provide automated and programmable feed rates, allowing for greater flexibility and control over the machining process. This ensures that operators can tailor the feed rates to their specific needs, whether it be for roughing, finishing, or any other machining operation. This level of customization not only improves the overall efficiency of the machining process, but also reduces the risk of errors and inconsistencies, ultimately leading to higher quality end products.In addition, the Power Cross Feed is designed to be incredibly user-friendly, making it accessible to a wide range of operators with varying levels of experience. Its intuitive interface and simple controls allow operators to quickly and easily familiarize themselves with the technology, minimizing the need for extensive training and maximizing productivity from the get-go.Furthermore, the Power Cross Feed is built with durability and reliability in mind, ensuring that it can withstand the rigorous demands of the machinery industry. [Company Name] is known for their commitment to quality, and the Power Cross Feed is no exception. Its robust design and high-quality construction make it a reliable and long-lasting investment for any machining operation.The introduction of the Power Cross Feed is a testament to [Company Name]'s dedication to innovation and excellence in the machinery industry. With over [number of years] years of experience, [Company Name] has established itself as a trusted leader in the field, constantly pushing the boundaries of what is possible. The Power Cross Feed is just the latest in a long line of groundbreaking technologies that [Company Name] has brought to market, and it is already making a significant impact on the industry.Industry professionals and customers alike are taking notice of the Power Cross Feed and its potential to revolutionize the machinery industry. With its ability to improve efficiency, precision, and productivity, this technology is quickly becoming a must-have for any modern machining operation. As [Company Name] continues to push the envelope with their advancements in technology, the Power Cross Feed is sure to solidify their position as a driving force in the machinery industry.In conclusion, the Power Cross Feed is a game-changing technology that is poised to transform the machinery industry. With its advanced capabilities, user-friendly design, and superior reliability, it is no wonder that [Company Name] is at the forefront of innovation in the industry. As they continue to develop and refine their technologies, [Company Name] is setting the bar higher for performance and productivity, and the Power Cross Feed is just the beginning of what they have to offer.

The world of CNC milling has experienced a remarkable transformation over the years, and today, individuals can access high-quality desktop milling machines at affordable prices. Desktop milling machines have opened up opportunities for hobbyists and small businesses by providing a cost-effective way to create precision parts out of a variety of materials. In this blog, we will explore different types of desktop milling machines, their benefits, and how they have revolutionized the manufacturing industry.One of the most affordable desktop milling machines is the DIY CNC Router Kits 2418 GRBL Control 3 Axis Carving Milling Engraving Machine, which retails at $239.99. It's an excellent entry-level option for DIY enthusiasts and beginners who want to create precision parts. The machine is easy to assemble and comes with a user-friendly control software.Alternatively, the STEPCRAFT-2/300 and STEPCRAFT-2/840 Desktop CNC Milling Machines made in Germany offer a more robust milling experience. These machines are designed to handle larger and more complex jobs. The STEPCRAFT-2/840 retails at $2,700.00, making it a bit pricier than the DIY CNC Router Kits 2418 but offers more advanced capabilities. It's worth mentioning that all StepCraft milling machines come with a 2-year warranty, making them an excellent investment for small businesses.For those who want to create 3D carvings, the USB CNC Router 4-axis 6040 1.5KW Spindle Engraving Milling 3D Carving machine is a great option. This machine offers superior precision when handling complex 3D designs and retails at $1,185.00. It comes with a USB interface for easy data transfer and compatibility with various software.The 3 Axis 3018 GRBL Control Mini CNC Router Milling Wood Engraving Machine Printer and the Mini 3 Axis 3018 CNC Laser Machine Carving Milling Router Engraver GRBL Control are other affordable options for those on a budget. They retail at $222.88 and $194.00, respectively, and are suitable for both hobbyists and professionals.If you're looking for a more advanced option, then the 4 AXIS ENGRAVER USB CNC6040Z ROUTER ENGRAVING DRILLING MILLING MACHINE 3D CUTTER is worth considering. It's designed for both industrial and personal use and retails at $1,097.90. The machine's 4-axis controller allows for complex jobs to be completed with ease.The DIY 2417 Mini Engraving Milling Machine Engraver CNC Router PCB Metal Desktop is also an excellent option for those on a tight budget. At $202.40, this desktop milling machine is affordable yet powerful. It's easy to assemble, allowing beginners to create precision parts with ease.Finally, the 4 Axis CNC 3040 Router Engraving Drilling Milling Woodworking Machine 3D Printer is an ideal choice for woodworking enthusiasts. Priced at $619.00, this machine is designed to work with a variety of materials, including wood, plastic, and metal.Desktop milling machines have revolutionized the manufacturing industry by providing an affordable and accessible way to create precision parts from a variety of materials. These machines have applications in various fields, such as education, engineering, prototyping, and small scale production. The future of desktop milling machines is bright, and as technology advances, we can expect to see even more advanced machines hitting the market.In conclusion, desktop milling machines offer a cost-effective way for hobbyists, DIY enthusiasts, and small businesses to create precision parts. Regardless of your budget or skill level, there's a desktop milling machine that's suitable for your needs. The machines covered in this blog offer a wide range of applications and features, making them an excellent investment for anyone looking to improve their prototyping or production capabilities. When looking to purchase a desktop milling machine, consider the features, capabilities, and price to ensure you select the right machine for your needs.

High-Quality Boring Bar Sleeve Holder for Efficient Machining Operations

Boring Bar Sleeve Holder - A Revolutionary Innovation in Machining TechnologyIn the world of machining, precision and efficiency are key factors for success. Every machinist and engineer knows the importance of using the right tools and equipment to achieve the highest possible level of precision in their work. With advancements in technology, the machining industry has seen the development of new and innovative tools that have revolutionized the way parts are manufactured.One such revolutionary innovation is the Boring Bar Sleeve Holder, a game-changing tool that has taken the machining industry by storm. This cutting-edge tool is designed to improve the accuracy and efficiency of boring operations, making it an essential component in any machining operation.The Boring Bar Sleeve Holder is a product of years of research and development by a leading machining equipment manufacturer. The company behind this innovative tool has been at the forefront of the machining industry, providing high-quality tools and equipment to machinists and engineers around the world.With a strong commitment to innovation and excellence, the company has continuously pushed the boundaries of machining technology. Their team of dedicated engineers and designers have worked tirelessly to develop new and improved tools that meet the ever-evolving needs of the machining industry.The Boring Bar Sleeve Holder is a testament to the company's dedication to innovation. This cutting-edge tool is designed to provide machinists with a reliable and efficient solution for boring operations, ensuring high levels of precision and accuracy in every job.One of the key features of the Boring Bar Sleeve Holder is its unique design, which allows for quick and easy tool changes. This means that machinists can save valuable time during machining operations, improving overall productivity and efficiency.Additionally, the Boring Bar Sleeve Holder is manufactured using high-quality materials, ensuring durability and longevity. This means that machinists can rely on this tool for years to come, making it a valuable investment for any machining operation.The Boring Bar Sleeve Holder is also designed to be versatile, accommodating a wide range of boring bar sizes. This flexibility allows machinists to use this tool for a variety of applications, making it a valuable and essential addition to any machining toolkit.In addition to its practical features, the Boring Bar Sleeve Holder is also designed with safety in mind. The company has implemented strict quality control measures to ensure that every tool meets the highest safety standards, providing machinists with peace of mind during their operations.The Boring Bar Sleeve Holder has already made a significant impact in the machining industry, earning rave reviews from machinists and engineers alike. Its innovative design and practical features have set a new standard for boring operations, making it a must-have tool for any machining operation.With the introduction of the Boring Bar Sleeve Holder, the company behind this revolutionary tool has once again proven its commitment to excellence and innovation in the machining industry. Their dedication to providing high-quality tools and equipment has solidified their position as a leader in the industry, and the Boring Bar Sleeve Holder is a shining example of their continued success.As the machining industry continues to evolve, innovative tools like the Boring Bar Sleeve Holder will play a crucial role in shaping the future of manufacturing. With its practical features and reliable performance, this revolutionary tool is set to become a staple in machining operations around the world.In conclusion, the Boring Bar Sleeve Holder is a game-changing innovation that has redefined the way machinists approach boring operations. With its practical features, high-quality construction, and versatile design, this revolutionary tool is a testament to the company's commitment to excellence and innovation in the machining industry. As the demand for precision and efficiency continues to grow, the Boring Bar Sleeve Holder is poised to become an essential tool for machinists and engineers worldwide.

Find Great Deals on High-Quality Lathe Chucks & Accessories online

Title: Exploring the Convenience and Versatility of Lathe Four-Jaw ChucksIntroduction:Lathe machines are crucial pieces of equipment in various commercial and industrial settings. They are primarily used for shaping and cutting materials, enabling precision and efficiency. One essential accessory for lathes is the four-jaw chuck. In this blog, we will dive into the convenience, versatility, and importance of utilizing a four-jaw chuck in lathe operations.Section 1: Understanding Lathe Four-Jaw Chucks- Introduction to lathe four-jaw chucks- Exploring the mechanics and structure of a four-jaw chuck- Understanding the purpose and role of each jaw in gripping and securing workpiecesSection 2: Benefits and Advantages of Four-Jaw Chucks in Lathe Operations1. Enhanced Grip and Stability: - Highlighting the ability of four-jaw chucks to hold irregularly shaped workpieces securely. - Discussing the versatility of independent jaw movement, allowing precise positioning for various materials.2. Time and Labor Savings: - Exploring the convenience of quickly centering and adjusting workpieces. - Discussing the time-saving capabilities of changing the gripping diameter without removing workpieces.3. Accommodation of Different Workpiece Sizes: - Discussing the adjustable nature of four-jaw chucks, allowing them to handle various dimensions of workpieces. - Highlighting the flexibility in gripping both small and large workpieces, reducing the need for additional tooling.4. Versatility in Clamping Options: - Exploring the ability to grip both internally and externally. - Discussing the advantages of utilizing the four-jaw chuck when facing, boring, and turning operations are required.Section 3: Selection and Maintenance of Four-Jaw Chucks1. Factors to Consider while Selecting a Four-Jaw Chuck: - Discussing the importance of considering chuck size, jaw types, and quality. - Highlighting considerations for different materials and machining operations.2. Proper Maintenance to Enhance Longevity: - Exploring the importance of cleaning and lubricating four-jaw chucks. - Discussing regular inspection and jaw readjustment to ensure optimal performance.Section 4: Applications and Use Cases of Four-Jaw Chucks- Discussing common industries and applications that heavily rely on four-jaw chucks.- Highlighting the use of four-jaw chucks in shaping, drilling, milling, and more.Conclusion:From their ability to handle irregularly shaped workpieces to the quick adjustment and centering features, lathe four-jaw chucks offer convenience, versatility, and enhanced productivity in lathing operations. Global Industrial, a leading distributor of commercial and industrial equipment, provides high-quality four-jaw chucks and accessories to meet the diverse needs of various industries. By harnessing the convenience and flexibility of four-jaw chucks, businesses can significantly improve their machining processes, delivering superior results in terms of accuracy and efficiency.Keywords: lathe four-jaw chuck, lathe chuck accessories, four-jaw chucks in lathe operations, versatility of four-jaw chucks, benefits of four-jaw chucks, selecting a four-jaw chuck, maintaining four-jaw chucks, lathe operations with four-jaw chucks.

Essential information about the Handler 190 extension cord

Hobart Handler 190 Extension Cord Recalled for Safety Concerns(Sample Company) is a leading manufacturer of industrial and commercial equipment, with a focus on providing high-quality products for a wide range of applications. The company prides itself on its commitment to safety and reliability, and is dedicated to ensuring that its products meet the highest standards for performance and quality.Recently, the company announced a recall of the (Sample Company) Extension Cord, which is used with the popular Hobart Handler 190 welder. The recall was initiated after it was discovered that the extension cord may pose a potential safety hazard, putting users at risk of electric shock or fire.The (Sample Company) Extension Cord is designed for use with the Hobart Handler 190 welder, which is a versatile and powerful welding machine used in various industries. The cord is intended to provide additional reach and flexibility for users, allowing them to work in a wider range of environments. However, it has come to the company's attention that the cord may not meet the necessary safety standards, and as a result, a recall has been issued to address the issue.The company is urging all customers who have purchased the (Sample Company) Extension Cord for use with the Hobart Handler 190 welder to discontinue use immediately and return the product for a full refund or replacement. The safety and satisfaction of customers is of utmost importance to the company, and it is taking swift and decisive action to remedy the situation.In a statement, a spokesperson for (Sample Company) emphasized the company's commitment to safety and quality. "We take the safety of our customers very seriously, and we deeply regret any inconvenience or concern that this recall may cause," the spokesperson said. "We are working diligently to rectify the situation and ensure that our customers have access to a safe and reliable extension cord for their welding needs."The (Sample Company) Extension Cord recall serves as a reminder of the importance of thorough testing and quality control in the manufacturing process. (Sample Company) is dedicated to upholding the highest standards for its products, and this incident underscores the company's commitment to addressing any issues that may compromise safety or performance.Customers who have purchased the (Sample Company) Extension Cord can contact the company's customer service department for information on how to return the product and receive a refund or replacement. The company is also working to ensure that all retailers carrying the product are aware of the recall and are taking appropriate measures to notify their customers.In the meantime, the company is conducting a thorough investigation to determine the root cause of the safety concern and to implement steps to prevent similar issues from arising in the future. The (Sample Company) team is dedicated to learning from this experience and using it to further improve the safety and reliability of its products.For customers who rely on the Hobart Handler 190 welder for their professional or personal needs, (Sample Company) is committed to providing a seamless and safe welding experience. The company stands behind the quality and performance of the welder itself and is dedicated to ensuring that customers have access to the tools and equipment they need to complete their work with confidence.As (Sample Company) works to address the extension cord recall, it is reinforcing its core values of safety, integrity, and customer satisfaction. The company is grateful for the ongoing support and trust of its customers, and is determined to uphold its reputation as a leader in providing top-quality industrial and commercial equipment.In conclusion, the (Sample Company) Extension Cord recall serves as a reminder of the importance of prioritizing safety and quality in the manufacturing and distribution of products. By taking swift and decisive action to address the safety concern, (Sample Company) is upholding its commitment to customer satisfaction and reaffirming its dedication to providing reliable and high-performance equipment for a wide range of applications.

Upgraded CNC Machine Handle Wheel: A Game-Changing Innovation in Manufacturing

Title: Advanced CNC Machine Handle Wheel - Revolutionizing Precision ManufacturingIntroduction:In the fast-paced world of manufacturing, technological advancements form the backbone of innovation. One such revolutionary development is the newest CNC Machine Handle Wheel, a groundbreaking addition in the field of precision manufacturing. Developed by a leading company, this handle wheel is poised to disrupt traditional machining processes. With its cutting-edge features and unparalleled precision, it is set to redefine the way manufacturers operate. In this article, we will delve into the exceptional capabilities of this CNC handle wheel and discuss the potential impact it may have on the manufacturing industry.Unleashing Precision:The CNC Machine Handle Wheel represents a leap forward in precision engineering. Engineered with utmost precision, it enables manufacturers to achieve exceptional accuracy and repeatability in their machining operations. The advanced design ensures minimal backlash, providing smoother and more precise movements, ultimately resulting in superior workpiece quality. This technological advancement will undoubtedly elevate the standards of precision manufacturing by enabling manufacturers to produce components with unprecedented accuracy.Enhanced Efficiency:Efficiency is a paramount concern for manufacturers aiming to minimize production time while maintaining optimal output. The CNC Machine Handle Wheel is equipped with state-of-the-art features that expedite machining processes. Its high-response control mechanism enables rapid adjustments and positions, reducing setup time significantly. Moreover, the integration of an intuitive user interface ensures ease of operation, allowing even novice operators to achieve professional-grade results. This increase in efficiency translates into reduced production costs and enhanced productivity for manufacturers.Versatility Redefined:Versatility is a key attribute when it comes to machining applications. The CNC Machine Handle Wheel offers unparalleled versatility, accommodating a wide range of machining requirements. With its adaptable design, it seamlessly integrates with various CNC machining centers, enhancing their capabilities without the need for excessive upgrades. The handle wheel's universal compatibility ensures that both small-scale workshops and large industrial plants can benefit from its exceptional performance, making it an ideal choice for any manufacturing setup.Ensuring Operator Safety:Safety is a paramount concern in manufacturing environments, prompting the need for cutting-edge solutions that protect operators from potential hazards. The CNC Machine Handle Wheel incorporates advanced safety features to ensure operator well-being. An intelligent emergency-stop button and an automatic shutdown mechanism are integrated into the design, mitigating risks and preventing unintended accidents. These safety measures provide peace of mind to operators, allowing them to focus on their tasks without compromising their safety.Environmental Sustainability:Manufacturers are increasingly cognizant of the environmental impact of their operations. The CNC Machine Handle Wheel aligns with this concern, offering energy-efficient operation. Its power-saving features result in reduced electricity consumption, minimizing carbon footprint. As the manufacturing industry continues to shift towards sustainable practices, this eco-friendly attribute of the handle wheel makes it a forward-thinking choice for companies striving for a greener future.Conclusion:The CNC Machine Handle Wheel represents a new era of precision manufacturing. With its unparalleled accuracy, enhanced efficiency, versatility, and commitment to operator safety and environmental sustainability, it has the potential to revolutionize the industry. As manufacturers continue to seek cutting-edge solutions to stay competitive, this advanced CNC handle wheel stands as a symbol of progress in the field. As its implementation becomes widespread, it is certain to drive advancements across various sectors and contribute to the evolution of manufacturing processes.

High-Quality 25m Wire Feeder for Welding Applications

The Lincoln 25m Wire Feeder is a cutting-edge piece of industrial equipment that has been making waves in the manufacturing and welding industries since its launch. This state-of-the-art wire feeder is designed to provide exceptional performance and reliability, making it an indispensable tool for businesses of all sizes.The wire feeder is manufactured by a leading company in the welding industry, which has been a pioneer in developing innovative welding solutions for over 100 years. With a strong focus on research and development, the company has consistently delivered top-tier products that meet the demands of modern-day manufacturing and fabrication processes.The Lincoln 25m Wire Feeder is a testament to the company's commitment to excellence. It is equipped with advanced features that allow for seamless wire feeding, ensuring consistent and precise welds every time. The feeder is also designed to be highly user-friendly, with intuitive controls and a straightforward setup process, making it accessible to welders of all skill levels.One of the standout features of the wire feeder is its robust construction, which is designed to withstand the rigors of industrial work environments. This ensures that the feeder can endure heavy use and harsh conditions without compromising its performance, making it a reliable and long-lasting investment for businesses.In addition to its durability, the wire feeder is also equipped with advanced technology that enhances its efficiency and productivity. This includes features such as a digital display that provides real-time feedback on wire speed and voltage, as well as programmable settings that allow for customized welding parameters to be saved and easily accessed.The company behind the Lincoln 25m Wire Feeder is dedicated to providing comprehensive support to its customers. This includes offering extensive training and technical support to ensure that businesses can maximize the potential of the wire feeder and achieve the best possible results in their welding processes.Furthermore, the company's commitment to sustainability is reflected in the design and manufacturing of the wire feeder. With a focus on energy efficiency and minimizing environmental impact, the feeder is in line with the company's dedication to responsible and eco-friendly practices in all aspects of its operations.The Lincoln 25m Wire Feeder has already garnered widespread acclaim within the industry, with businesses praising its reliability, performance, and user-friendly design. Many have reported significant improvements in their welding processes and overall productivity since incorporating the wire feeder into their operations.Looking ahead, the company continues to push the boundaries of innovation with ongoing research and development efforts aimed at further enhancing the capabilities of the wire feeder. With a steadfast commitment to meeting the evolving needs of the manufacturing and welding industries, the company is well-positioned to remain a leader in delivering high-quality solutions like the Lincoln 25m Wire Feeder.In conclusion, the Lincoln 25m Wire Feeder represents a game-changing advancement in the field of welding technology. With its unparalleled performance, reliability, and user-friendly design, it has quickly become an essential tool for businesses looking to elevate their welding processes. Backed by a company with a rich history of innovation and a dedication to excellence, the wire feeder is poised to continue making a significant impact in the industry for years to come.