New Digital Readout Technology in the News

By:Admin

Since [year of establishment], [Company Name] has been a leading provider of digital readout systems for machinery. With a focus on precision and accuracy, they have consistently delivered top-notch products to their customers around the world. Their commitment to innovation and customer satisfaction has made them a trusted name in the industry.

One of [Company Name]'s flagship products is their digital readout system, which is a vital tool for machinists looking to achieve precise measurements and consistent results. The digital readout system offers a range of features including high-resolution displays, intuitive user interfaces, and advanced measurement capabilities. With [Company Name]'s digital readout system, machinists can improve their productivity, reduce errors, and ultimately, deliver better results for their clients.

One of the key advantages of [Company Name]'s digital readout system is its versatility. It can be easily integrated into a wide range of machinery, including milling machines, lathes, grinders, and more. This flexibility makes it a popular choice for machinists across various industries, from automotive and aerospace to medical device manufacturing.

In addition to their high-quality products, [Company Name] is also renowned for their exceptional customer service. Their team of experts is always on hand to offer guidance and support to their clients, whether they need assistance with installation, troubleshooting, or general product inquiries.

Furthermore, [Company Name] is committed to staying at the forefront of technological advancements in the industry. They continuously invest in research and development to improve their products and offer innovative solutions to their customers. This dedication to innovation has allowed [Company Name] to stay ahead of the competition and meet the evolving needs of the industry.

In recent news, [Company Name] has unveiled their latest digital readout system, which promises even more advanced features and enhanced performance. The new system boasts improved accuracy, faster response times, and a more user-friendly interface, making it easier than ever for machinists to achieve precision in their work.

"We are thrilled to introduce our latest digital readout system to the market," said [Spokesperson's Name], [Company Name]'s [Title]. "With this new system, we aim to set a new standard for precision and reliability in the industry. We believe that it will empower machinists to take their work to the next level and deliver exceptional results for their clients."

The new digital readout system has already garnered a lot of attention from industry professionals, with many expressing excitement about the advanced features and potential impact on their work. With [Company Name]'s track record of delivering high-quality products and exceptional customer service, the new digital readout system is expected to be a game-changer for the industry.

As [Company Name] continues to push the boundaries of what is possible in the world of digital readout systems, it is clear that they are dedicated to empowering machinists with the tools they need to succeed. Their commitment to innovation, quality, and customer satisfaction sets them apart as a leader in the industry, and their latest product release is a testimony to their ongoing efforts to push the industry forward.

In conclusion, [Company Name] has built a strong reputation as a leading provider of digital readout systems, and their latest product release further solidifies their position in the industry. With a focus on precision, versatility, and innovation, [Company Name] continues to make waves in the industry and empower machinists to achieve outstanding results in their work.

Company News & Blog

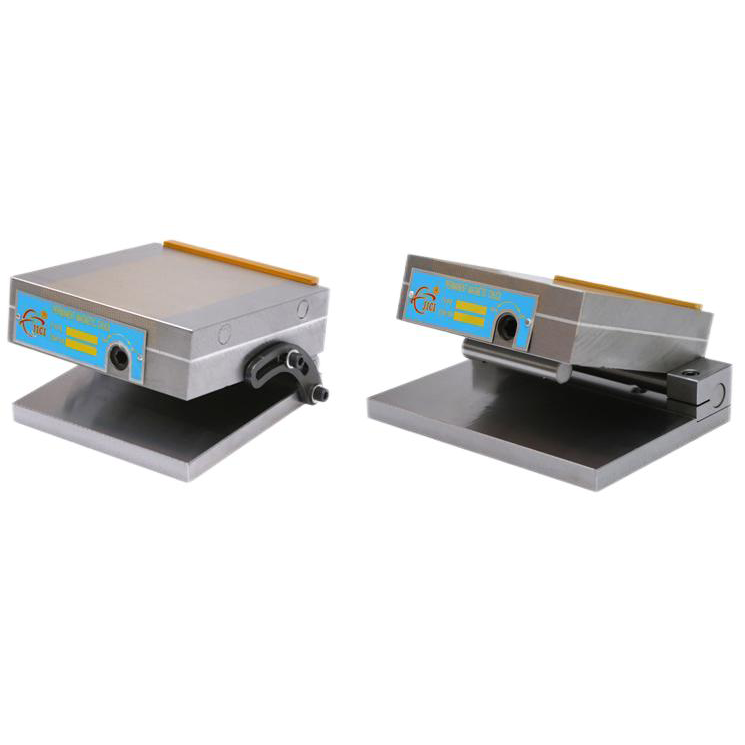

High-Precision Surface Grinder for Ball Needle Roller

Surface Grinder Ball Needle Roller Revolutionizes Precision Grinding in Manufacturing IndustryIn the world of precision grinding, the surface grinder ball needle roller has emerged as a game-changing innovation that is revolutionizing the manufacturing industry. Manufactured by a leading company in the field of precision engineering and machining, this innovative product is setting new standards for accuracy, efficiency, and reliability in the grinding of highly complex components.The surface grinder ball needle roller, developed and produced by a company that has been a pioneer in the field for over three decades, is designed to meet the growing demand for high-precision components in industries such as aerospace, automotive, medical devices, and many others. With its advanced technology and state-of-the-art manufacturing processes, this product has become an essential tool for manufacturers seeking to achieve the highest levels of precision and quality in their products.One of the key features of this surface grinder ball needle roller is its ability to grind complex geometries with unparalleled accuracy and consistency. This is made possible by its advanced ball and needle roller bearings, which are designed to minimize friction and ensure smooth and precise movement during the grinding process. As a result, manufacturers can achieve extremely tight tolerances and surface finishes that were previously unattainable with conventional grinding methods.Furthermore, the surface grinder ball needle roller is equipped with a highly efficient coolant system, which eliminates the risk of thermal damage to the workpiece and enables continuous grinding operations without the need for frequent interruptions. This feature is particularly important for manufacturers working with heat-sensitive materials, as it allows them to maintain the integrity of the workpiece throughout the entire grinding process.In addition to its superior precision and efficiency, the surface grinder ball needle roller also offers unmatched versatility, thanks to its ability to accommodate a wide range of component sizes and shapes. This flexibility makes it an ideal solution for manufacturers working on a variety of projects, from small, intricate parts to large, complex assemblies.The company behind the surface grinder ball needle roller takes great pride in its commitment to research and development, ensuring that its products are constantly evolving to meet the ever-changing needs of the industry. With a team of highly skilled engineers and technicians, the company continuously pushes the boundaries of precision engineering, seeking new ways to enhance the performance and capabilities of its products.Moreover, the company has invested heavily in state-of-the-art manufacturing facilities, equipped with the latest technologies and automated systems to ensure the highest levels of quality and consistency in its products. This commitment to excellence has earned the company a reputation for being a trusted partner for manufacturers seeking cutting-edge solutions for their precision grinding needs.As the demand for high-precision components continues to grow across various industries, the surface grinder ball needle roller is poised to play a pivotal role in shaping the future of manufacturing. Its ability to deliver exceptional precision, efficiency, and versatility makes it an indispensable tool for manufacturers seeking to stay ahead of the competition and elevate their products to new heights of quality and performance.In conclusion, the surface grinder ball needle roller stands as a testament to the relentless pursuit of innovation and excellence in the field of precision engineering and machining. Its impact on the manufacturing industry is undeniable, and it is poised to continue setting new standards for precision grinding, driving the industry forward into a new era of possibilities. With its advanced technology, exceptional performance, and unwavering commitment to quality, the surface grinder ball needle roller has earned its place as a pioneering force in the world of precision engineering.

High-Quality Machine Spare Parts for Lathes

[Company Name], a leading provider of machine spare parts for lathes, has announced the launch of their latest range of spare parts for industrial lathes. With a focus on quality, reliability, and precision, [Company Name] has established a strong reputation in the industry for providing high-quality spare parts to meet the diverse needs of their customers.The new range of spare parts for industrial lathes includes a variety of components such as chucks, tool posts, cutting tools, and other essential parts that are vital for the smooth and efficient operation of lathes in industrial settings. These spare parts are designed to meet the highest standards of quality and performance, ensuring that they can withstand the demanding conditions of industrial operations.[Company Name] has been at the forefront of the industry for many years, and their commitment to excellence has earned them a loyal customer base. With a team of experienced engineers and technicians, [Company Name] is able to develop and produce spare parts that are not only of the highest quality but also tailored to the specific requirements of their customers.In addition to their focus on quality, [Company Name] also takes pride in their ability to provide exceptional customer service. With a dedicated team of customer support representatives, [Company Name] ensures that their customers receive the assistance they need to select the right spare parts for their lathes and to address any technical issues that may arise.The launch of the new range of spare parts for industrial lathes is a testament to [Company Name]'s commitment to innovation and continuous improvement. By investing in research and development, [Company Name] is able to stay ahead of the curve and anticipate the evolving needs of their customers. This allows them to provide solutions that are not only reliable and efficient but also ensure that their customers can maintain the highest levels of productivity in their operations.As [Company Name] continues to expand its range of spare parts for industrial lathes, they are also exploring opportunities to further improve their manufacturing processes and enhance the performance of their products. By leveraging the latest technologies and manufacturing techniques, [Company Name] aims to deliver spare parts that not only meet the current industry standards but also set new benchmarks for quality and reliability.With their strong track record of delivering high-quality spare parts and their unwavering commitment to customer satisfaction, [Company Name] is well-positioned to continue leading the industry in the provision of machine spare parts for lathes. Their latest range of spare parts for industrial lathes is set to further solidify their position as a trusted partner for industrial businesses seeking top-notch solutions for their machinery requirements.For businesses looking to enhance the performance and reliability of their lathes, the new range of spare parts from [Company Name] presents an exciting opportunity to access top-quality components that are designed to withstand the rigors of industrial operations. With their focus on quality, innovation, and customer service, [Company Name] is poised to continue setting the standard for excellence in the industry.

Advantages of High Speed Milling Machines for Precision Manufacturing

XYZ Corporation Introduces High Speed Milling Machine for Precision MachiningXYZ Corporation, a leading manufacturer of advanced CNC machines, has introduced a new High Speed Milling Machine. This state-of-the-art machine is designed to provide precision machining with high speed and accuracy, making it an ideal solution for companies in the aerospace, automotive, and medical device industries.The High Speed Milling Machine is equipped with advanced technology that allows for faster cutting and higher precision. This cutting-edge machine can process a wide range of materials, including aluminum, stainless steel, titanium, and composites, with exceptional efficiency and quality.With its high-speed spindle and rapid tool change capability, the High Speed Milling Machine is capable of reducing production times and increasing productivity. This innovative machine also features a rigid and stable structure, which ensures excellent surface finishes and precise dimensions, meeting the stringent requirements of modern manufacturing.“Our new High Speed Milling Machine is the result of years of research and development, as well as feedback from our customers. We are excited to introduce a machine that offers exceptional speed, accuracy, and reliability, setting a new standard in precision machining,” said the CEO of XYZ Corporation.In addition to its advanced capabilities, the High Speed Milling Machine is also designed for ease of use and maintenance. Its user-friendly interface and intuitive controls make it simple for operators to set up and operate the machine, while the machine’s modular design allows for easy access for maintenance and servicing.XYZ Corporation takes pride in its commitment to delivering innovative solutions that meet the ever-evolving needs of the manufacturing industry. The introduction of the High Speed Milling Machine is another example of the company’s dedication to providing cutting-edge technology that empowers its customers to achieve greater efficiency and success in their operations.With its robust construction and high-performance capabilities, the High Speed Milling Machine is poised to become a valuable asset for companies seeking to enhance their machining processes and stay ahead in a competitive market. It offers a cost-effective solution for achieving high-quality results in a shorter amount of time, ultimately contributing to improved profitability and customer satisfaction.As a company that values customer satisfaction and long-term partnerships, XYZ Corporation provides comprehensive support and service for its High Speed Milling Machine. The company’s team of experienced technicians is available to assist customers with installation, training, and ongoing maintenance, ensuring the optimal performance and longevity of the machine.In conclusion, XYZ Corporation’s introduction of the High Speed Milling Machine signifies a significant advancement in precision machining technology. The machine’s high speed, accuracy, and reliability make it a game-changer for manufacturers seeking to streamline their operations and deliver superior products to their customers. With its commitment to innovation and customer satisfaction, XYZ Corporation continues to be a trusted partner for companies looking to elevate their manufacturing capabilities.

Find Great Deals on High-Quality Lathe Chucks & Accessories online

Title: Exploring the Convenience and Versatility of Lathe Four-Jaw ChucksIntroduction:Lathe machines are crucial pieces of equipment in various commercial and industrial settings. They are primarily used for shaping and cutting materials, enabling precision and efficiency. One essential accessory for lathes is the four-jaw chuck. In this blog, we will dive into the convenience, versatility, and importance of utilizing a four-jaw chuck in lathe operations.Section 1: Understanding Lathe Four-Jaw Chucks- Introduction to lathe four-jaw chucks- Exploring the mechanics and structure of a four-jaw chuck- Understanding the purpose and role of each jaw in gripping and securing workpiecesSection 2: Benefits and Advantages of Four-Jaw Chucks in Lathe Operations1. Enhanced Grip and Stability: - Highlighting the ability of four-jaw chucks to hold irregularly shaped workpieces securely. - Discussing the versatility of independent jaw movement, allowing precise positioning for various materials.2. Time and Labor Savings: - Exploring the convenience of quickly centering and adjusting workpieces. - Discussing the time-saving capabilities of changing the gripping diameter without removing workpieces.3. Accommodation of Different Workpiece Sizes: - Discussing the adjustable nature of four-jaw chucks, allowing them to handle various dimensions of workpieces. - Highlighting the flexibility in gripping both small and large workpieces, reducing the need for additional tooling.4. Versatility in Clamping Options: - Exploring the ability to grip both internally and externally. - Discussing the advantages of utilizing the four-jaw chuck when facing, boring, and turning operations are required.Section 3: Selection and Maintenance of Four-Jaw Chucks1. Factors to Consider while Selecting a Four-Jaw Chuck: - Discussing the importance of considering chuck size, jaw types, and quality. - Highlighting considerations for different materials and machining operations.2. Proper Maintenance to Enhance Longevity: - Exploring the importance of cleaning and lubricating four-jaw chucks. - Discussing regular inspection and jaw readjustment to ensure optimal performance.Section 4: Applications and Use Cases of Four-Jaw Chucks- Discussing common industries and applications that heavily rely on four-jaw chucks.- Highlighting the use of four-jaw chucks in shaping, drilling, milling, and more.Conclusion:From their ability to handle irregularly shaped workpieces to the quick adjustment and centering features, lathe four-jaw chucks offer convenience, versatility, and enhanced productivity in lathing operations. Global Industrial, a leading distributor of commercial and industrial equipment, provides high-quality four-jaw chucks and accessories to meet the diverse needs of various industries. By harnessing the convenience and flexibility of four-jaw chucks, businesses can significantly improve their machining processes, delivering superior results in terms of accuracy and efficiency.Keywords: lathe four-jaw chuck, lathe chuck accessories, four-jaw chucks in lathe operations, versatility of four-jaw chucks, benefits of four-jaw chucks, selecting a four-jaw chuck, maintaining four-jaw chucks, lathe operations with four-jaw chucks.

High-Quality 3 Jaw Chuck for Lathe: A Must-Have Tool for Precision Machining

[Company Name], a leading manufacturer of precision machining equipment, has recently launched a new 3-jaw chuck for lathes. This new addition to their product line is designed to provide enhanced gripping and precision machining capabilities for a wide range of industrial applications.The 3-jaw chuck is an essential tool for lathes, used for holding and rotating cylindrical workpieces during machining. The new chuck from [Company Name] is crafted with high-quality materials and precision engineering to ensure optimal performance and durability.One of the key features of the new 3-jaw chuck is its gripping strength and accuracy. The chuck is designed to securely hold workpieces in place during machining operations, preventing slippage and ensuring precise and consistent machining results. This is especially important for industries such as automotive, aerospace, and manufacturing, where tight tolerances and high-quality finishes are critical.In addition to its gripping capabilities, the new 3-jaw chuck also offers quick and easy installation, making it a convenient and efficient tool for machinists. The chuck is compatible with a wide range of lathe models, making it a versatile option for industrial workshops and manufacturing facilities.[Company Name] prides itself on its commitment to innovation and quality, and the new 3-jaw chuck is a testament to this. The company has a long-standing reputation for delivering high-performance machining solutions to its customers, and the new chuck is a welcome addition to its product portfolio.With a focus on customer satisfaction and continuous improvement, [Company Name] invests heavily in research and development to ensure that its products meet the ever-evolving needs of the industry. The new 3-jaw chuck is the result of extensive research and testing, and it is poised to set new standards for gripping and machining performance.In addition to its cutting-edge products, [Company Name] is also known for its exceptional customer service and technical support. The company works closely with its customers to understand their unique machining needs and provide tailored solutions that meet their requirements. This customer-centric approach has earned [Company Name] a loyal and satisfied customer base across the globe.As a global leader in the machining equipment industry, [Company Name] is dedicated to promoting the advancement of manufacturing technologies and empowering its customers to achieve greater efficiency and productivity. The new 3-jaw chuck is a reflection of this commitment, as it is designed to enable machinists to maximize their machining capabilities and deliver superior quality products.In summary, the new 3-jaw chuck from [Company Name] is set to make a significant impact in the machining industry, offering unparalleled gripping strength, precision, and versatility. With its launch, [Company Name] reinforces its position as a trusted partner for machining solutions and reaffirms its dedication to driving innovation and excellence in the industry.

Top 2 Axis Dro: Everything You Need to Know

[Company Name] Introduces New 2 Axis Dro for Enhanced Precision in Manufacturing[City], [Date] - [Company Name] is proud to announce the launch of their latest 2 Axis Dro, a cutting-edge digital readout system designed to provide precision and accuracy in machine tool processes. This new addition to their product line is set to revolutionize the manufacturing industry by offering advanced features and functionality.The 2 Axis Dro is a digital readout system that provides real-time positioning feedback for machine tools such as lathes, milling machines, and grinders. It is designed to improve productivity and accuracy in the manufacturing process by enabling operators to monitor and control the positioning of the workpiece with high precision.With its advanced capabilities, the 2 Axis Dro offers a range of benefits for manufacturing companies. It provides accurate positioning feedback, reducing the risk of errors and ensuring consistent and high-quality products. Additionally, it enhances the efficiency of machine tool processes, leading to increased productivity and reduced production costs."We are thrilled to introduce our latest 2 Axis Dro to the market," said [Spokesperson Name], CEO of [Company Name]. "This innovative digital readout system is a result of our commitment to providing cutting-edge technology solutions for the manufacturing industry. We believe that it will make a significant impact on the way machine tool processes are carried out, leading to improved efficiency and precision."The 2 Axis Dro is equipped with a user-friendly interface, making it easy for operators to set up and use. It also offers a range of advanced features, including programmable memory, taper calculation, and customizable display options. These features are designed to meet the diverse needs of manufacturing companies and provide them with the tools they need to optimize their machine tool processes.In addition to its advanced features, the 2 Axis Dro is built to withstand the rigors of industrial environments. It is constructed with durable materials and undergoes rigorous testing to ensure reliable performance in demanding manufacturing settings. This makes it a reliable and long-lasting solution for companies looking to enhance the precision and accuracy of their machine tool processes.The introduction of the 2 Axis Dro further solidifies [Company Name]'s position as a leading provider of technology solutions for the manufacturing industry. With a strong focus on innovation and quality, the company has established a reputation for delivering high-performance products that meet the evolving needs of the market."We are committed to supporting the success of our customers by providing them with the tools they need to thrive in today's competitive manufacturing landscape," added [Spokesperson Name]. "The 2 Axis Dro exemplifies our dedication to innovation and quality, and we are confident that it will deliver exceptional value to our customers."In conclusion, the launch of the new 2 Axis Dro by [Company Name] represents a significant milestone in the manufacturing industry. With its advanced features, durability, and user-friendly interface, this digital readout system is set to empower manufacturing companies with enhanced precision and accuracy in their machine tool processes. [Company Name] continues to demonstrate its commitment to driving innovation and excellence in the manufacturing industry, and the 2 Axis Dro is a testament to this ongoing dedication.

Discover the Latest Power Feed Innovation for Optimal Results

: Revolutionizing Your Machining ProcessIn today's manufacturing industry, precision and efficiency are essential factors to meet the increasing demands of consumers. The Servo Dynamo Power Feed (SDPF) is a revolutionary product that brings automation and convenience to the machining process.The SDPF is a motorized power feed that is compatible with a wide range of milling machines. It is designed to simplify the milling process and increase productivity by automating the table feed mechanism. The product comes with an easy-to-install mounting bracket that makes it simple to attach to the milling machine.One of the key advantages of the SDPF is its smooth and consistent table feed speed, which allows for precise milling operations. This ensures that the machining process is accurate and efficient, resulting in high-quality finished products. It also reduces the potential for operator errors, which can be costly and time-consuming.Another important benefit of the SDPF is its versatility. It is compatible with a variety of milling machines, including Bridgeport, Jet, and Sharp models. This makes it easy to integrate into any existing manufacturing setup, without the need for additional equipment.The SDPF also offers a range of speed options, which can be adjusted to suit the specific milling requirements of different materials. This flexibility allows users to achieve optimum results for different cutting applications, such as roughing and finishing operations.One of the most significant advantages of the SDPF is its ease of use. It is a plug-and-play device that can be installed and operated without any extensive training or experience. The product's user-friendly interface makes it simple to adjust the feed speed, and a digital display provides real-time information on the machining process.Overall, the Servo Dynamo Power Feed is a game-changer in the machining industry. It provides a range of benefits that improve the efficiency, accuracy, and simplicity of the milling process. With its versatility, precision, and ease of use, the SDPF is a valuable addition to any manufacturing facility that wants to stay ahead of the competition.In Conclusion, the Servo Dynamo Power Feed is one of the best products in the market that offers automation and convenience to the machining process. It revolutionizes the industry by enhancing precision and efficiency. The SDPF is versatile, easy to use, and it is suitable for different milling machines. It is a game-changer that simplifies the machining process and makes it efficient, accurate, and time-saving. If you are looking to transform your manufacturing setup, then the Servo Dynamo Power Feed is a must-have product that you must consider.

High-Quality Rotary Switches for Versatile Applications

[Company Introduction]Established in 1998, our company has been a leading manufacturer of electrical components in the industry. We specialize in the production of high-quality switches, connectors, and other electrical parts that are used in various applications including industrial machinery, consumer electronics, and automotive systems. With a commitment to innovation and customer satisfaction, we have continuously improved our products and services to meet the ever-changing demands of the market.Our state-of-the-art manufacturing facilities, along with a team of experienced engineers and technicians, enable us to produce reliable and durable components that are trusted by our customers worldwide. In addition to our standard product line, we also offer custom solutions to meet specific requirements, ensuring that our clients have access to the right electrical components for their applications.As part of our dedication to excellence, we constantly invest in research and development to stay at the forefront of technological advancements. This allows us to introduce new and improved products that address the evolving needs of the industry. Furthermore, our rigorous quality control measures ensure that every product that leaves our facility meets the highest standards for performance and safety.With a strong focus on sustainability, we strive to minimize our environmental impact by incorporating eco-friendly practices in our manufacturing processes. We are committed to operating in an environmentally responsible manner and to developing products that contribute to a more sustainable future.[Rotary Switch News]We are pleased to announce the launch of our latest innovation, the Rotary Switch, designed to meet the growing demand for reliable and versatile electrical components. The Rotary Switch is a high-performance device that offers exceptional durability and precision, making it an ideal choice for a wide range of applications.Featuring a sleek and ergonomic design, the Rotary Switch is engineered to provide smooth and accurate operation, allowing users to easily select different modes or settings with confidence. Whether it's used in control panels, electronic instruments, or industrial machinery, the Rotary Switch's intuitive interface ensures ease of use and enhances overall performance.One of the key advantages of the Rotary Switch is its versatility. With multiple contact arrangements and configurations available, it can accommodate various electrical requirements, making it a versatile solution for different systems and equipment. This flexibility not only simplifies integration but also helps reduce inventory costs by eliminating the need for multiple switch types.In addition to its technical capabilities, the Rotary Switch is built to withstand harsh working environments. Constructed with high-quality materials and precision engineering, it offers superior resistance to dust, moisture, and mechanical stress, ensuring reliable operation even in demanding conditions. This level of durability not only extends the lifespan of the switch but also reduces maintenance costs for end users.Furthermore, the Rotary Switch is designed with safety in mind. With features such as secure locking mechanisms and clear labeling, it helps prevent accidental misuse and ensures that electrical systems operate safely and efficiently. This attention to safety is crucial in industries where strict compliance with regulations and standards is essential.As with all our products, the Rotary Switch undergoes rigorous testing to ensure its performance and reliability. Our commitment to quality and customer satisfaction is reflected in the exceptional durability and precision of the Rotary Switch, and we are confident that it will exceed the expectations of our customers.In conclusion, the launch of the Rotary Switch represents another milestone in our ongoing commitment to delivering innovative and reliable electrical components to the market. With its versatility, durability, and safety features, the Rotary Switch sets a new standard for high-performance switching solutions. We are proud to offer this exciting product to our customers and look forward to its positive impact on various industries.

Top Metal Cutting Tools to Buy in 2021

In recent news, the metal cutting industry has seen a significant advancement in technology with the introduction of new cutting tools. With the increased demand for precision and efficiency in metal cutting processes, many companies are investing in state-of-the-art equipment to improve their manufacturing capabilities.One company that has been at the forefront of this technological advancement is {Company}. With over 20 years of experience in the industry, {Company} has been a pioneer in developing cutting-edge metal cutting tools that have set new standards for precision and performance.{Company} specializes in the design and manufacturing of a wide range of cutting tools, including end mills, drills, and reamers. Their products are known for their exceptional quality, durability, and high performance, making them a preferred choice for many clients in various industries.Recently, {Company} announced the launch of their latest cutting tool, the {Tool Name}. This new tool is designed to provide superior performance and precision, making it an ideal solution for today's most demanding metal cutting applications. The {Tool Name} has been engineered using advanced materials and innovative design, resulting in a cutting tool that delivers unparalleled accuracy and efficiency.With the introduction of the {Tool Name}, {Company} aims to further solidify its position as a leader in the metal cutting industry. The company's commitment to innovation and continuous improvement is reflected in the development of this new cutting tool, which is poised to set new benchmarks for performance and quality.To ensure the highest level of quality and performance, {Company} employs strict quality control measures throughout the manufacturing process. Each cutting tool undergoes rigorous testing and inspection to ensure that it meets the company's exacting standards. This dedication to quality has earned {Company} a reputation for delivering cutting tools that exceed customer expectations and industry standards.In addition to their cutting-edge products, {Company} is also known for its exceptional customer service and technical support. The company's team of experts is dedicated to providing clients with the guidance and support they need to select the right cutting tools for their specific applications. From product selection to after-sales support, {Company} is committed to ensuring that their clients receive the best possible experience.As the metal cutting industry continues to evolve, {Company} remains at the forefront of innovation, constantly exploring new technologies and techniques to improve their products and services. The introduction of the {Tool Name} is just one example of the company's commitment to pushing the boundaries of what is possible in metal cutting.With a solid reputation for quality, performance, and innovation, {Company} is well-positioned to continue leading the way in the metal cutting industry. As the demand for precision and efficiency in metal cutting processes continues to grow, companies can rely on {Company} to provide cutting-edge solutions that meet their evolving needs.In conclusion, the introduction of the {Tool Name} signals an exciting new chapter for {Company} and the metal cutting industry as a whole. With its exceptional performance and precision, this new cutting tool is set to make a significant impact on metal cutting processes, further cementing {Company}'s reputation as a leader in the industry.

Essential Accessories and Attachments for Milling Machines: A Complete Guide

Milling Machine Accessories And Attachments: Enhancing Precision and EfficiencyMilling machines are essential tools in the manufacturing and metalworking industries, used for shaping solid materials. These machines can perform a wide range of tasks, from simple drilling to complex operations such as milling, boring, and threading. To enhance their capabilities, accessories and attachments play a crucial role in expanding the functionality of milling machines.One of the leading providers of milling machine accessories and attachments is {}. With [number] years of experience in the industry, the company has established a strong reputation for delivering high-quality products that are designed to meet the diverse needs of its customers.The range of accessories and attachments offered by {} includes a variety of cutting tools, workholding devices, digital readouts, rotary tables, and power feeds. These accessories are designed to enhance the precision, efficiency, and versatility of milling machines, allowing users to achieve greater productivity and accuracy in their machining operations.One of the key accessories offered by {} is the digital readout system, which provides real-time feedback on the position of the cutting tool, allowing for precise control and measurement during the machining process. This enables operators to achieve greater accuracy and consistency in their work, leading to improved quality of the finished products.In addition to digital readouts, {} also offers a wide range of cutting tools, including end mills, face mills, and indexable inserts. These cutting tools are engineered with high-grade materials and advanced coatings to provide superior performance and extended tool life, resulting in cost savings for the users.Another essential accessory for milling machines is the rotary table, which allows for precise positioning of the workpiece, enabling the machining of complex shapes and contours. The rotary tables offered by {} are designed to deliver smooth and accurate rotation, making them ideal for tasks such as cutting gears, splines, and other intricate components.Workholding devices such as vices, clamps, and fixtures are also crucial accessories for milling machines, as they securely hold the workpiece in place during the machining process. {} offers a comprehensive range of workholding solutions that are designed to accommodate a wide variety of workpieces, ensuring stability and precision in machining operations.Furthermore, power feeds are an essential attachment for milling machines, as they automate the feed of the cutting tool, allowing for smoother and more consistent cutting operations. The power feeds offered by {} are designed to deliver precise control over the feed rate, resulting in improved surface finish and reduced operator fatigue.With a commitment to innovation and quality, {} continuously invests in research and development to introduce new and improved accessories and attachments for milling machines. The company’s team of engineers and technicians work tirelessly to incorporate the latest technologies and manufacturing processes into their products, ensuring that customers have access to cutting-edge solutions for their machining needs.In addition to offering a wide range of accessories and attachments, {} provides exceptional customer support, including technical assistance, training, and after-sales service. The company’s team of experts is dedicated to helping customers optimize the performance of their milling machines and achieve the best results in their machining operations.As the demand for precision and efficiency in manufacturing and metalworking continues to grow, the role of milling machine accessories and attachments becomes increasingly crucial. With its comprehensive range of high-quality products and dedication to customer satisfaction, {} remains a trusted partner for businesses seeking to enhance the capabilities of their milling machines and achieve superior results in their machining operations.