Complete Guide to Lathe Tailstock Assemblies: Everything You Need to Know

By:Admin

[City, Date] - [Company Name], a leading provider of precision engineering solutions, is pleased to introduce its latest innovation in the form of a high-performance Lathe Tailstock Assembly. This new addition to our product line is designed to enhance the efficiency and accuracy of manufacturing processes, catering to the growing demands of the industry for precision components and parts.

The Lathe Tailstock Assembly is a crucial component in the operation of a lathe machine, providing support and stability to the workpiece during the machining process. With [Company Name]'s extensive expertise in precision engineering, the new assembly is engineered to deliver exceptional performance and reliability, meeting the stringent requirements of modern manufacturing operations.

Key Features of the New Lathe Tailstock Assembly include:

Advanced Design: The assembly features a modern and ergonomic design, incorporating high-quality materials and precision engineering to ensure robustness and longevity in the most demanding manufacturing environments.

Precision Engineering: The Lathe Tailstock Assembly is built to deliver unparalleled levels of precision, allowing for accurate and repeatable machining processes for a wide range of workpieces.

Enhanced Stability: With a focus on stability and rigidity, the assembly provides a solid and secure support for the workpiece, minimizing vibration and ensuring consistent and high-quality machining results.

Versatile Applications: The new assembly is designed to accommodate a variety of workpieces and machining requirements, making it a versatile solution for manufacturers across different industries.

Speaking about the launch of the new Lathe Tailstock Assembly, [Company Name]'s spokesperson commented, "We are excited to introduce our latest innovation to the market. The new assembly reflects our commitment to delivering cutting-edge precision engineering solutions that empower manufacturers to achieve higher levels of efficiency and quality in their operations."

"The Lathe Tailstock Assembly is the result of extensive research and development, combined with our deep understanding of the evolving needs of the manufacturing industry. We believe that this new addition to our product range will make a significant impact on our customers' ability to meet the demands of modern manufacturing," the spokesperson added.

[City, Date] - [Company Name] has been at the forefront of precision engineering for over [X] years. Our dedication to innovation and excellence has earned us a reputation as a trusted partner for manufacturers seeking superior solutions for their machining and engineering needs.

With our state-of-the-art facilities and a team of highly skilled engineers and technicians, we are fully equipped to design, manufacture, and deliver precision components and assemblies that meet the highest standards of quality and performance.

At [Company Name], customer satisfaction is at the heart of everything we do. We work closely with our clients to understand their specific requirements and provide tailored solutions that address their unique challenges. Our commitment to customer service, combined with our technical expertise, sets us apart as a leader in the precision engineering industry.

As we continue to expand our product portfolio and explore new frontiers in engineering innovation, [Company Name] remains dedicated to pushing the boundaries of what is possible in precision machining. We are excited about the launch of our new Lathe Tailstock Assembly and the opportunities it presents for our customers to enhance their manufacturing capabilities.

For more information about [Company Name] and our range of precision engineering solutions, please visit our website [URL] or contact us at [Phone Number] or [Email Address].

About [Company Name]:

[Company Name] is a leading provider of precision engineering solutions, specializing in the design and manufacture of high-quality components and assemblies for the manufacturing industry. With a wealth of experience and a commitment to innovation, we deliver cutting-edge solutions that empower our clients to achieve higher levels of efficiency and quality in their operations.

Company News & Blog

The Ultimate Guide to Tapping Machines: Everything You Need to Know

The Tapping Machine: Revolutionizing Manufacturing ProcessesIn the world of manufacturing and production, efficiency and precision are key factors in ensuring the success of any company. With the constant evolution of technology and the increasing demand for high-quality products, it is imperative for businesses to invest in advanced machinery that can streamline their processes and enhance their productivity. One such piece of equipment that has been making waves in the manufacturing industry is the Tapping Machine, a powerful tool that is changing the way businesses approach their tapping operations.Tapping is a crucial process in manufacturing, as it involves creating screw threads inside a hole so that it can receive a bolt or a screw. Traditionally, tapping was a time-consuming and labor-intensive task that required skilled workers to manually operate a tap to create the necessary threads. However, with the advancement of technology, the introduction of the Tapping Machine has revolutionized the way tapping is done, offering a faster, more precise, and efficient alternative to traditional manual methods.The Tapping Machine, offered by {}, is a state-of-the-art piece of machinery that has quickly gained popularity among manufacturers for its ability to significantly improve tapping operations. With its advanced features and cutting-edge technology, this machine has set a new standard for tapping processes, offering numerous benefits to businesses looking to enhance their production capabilities.One of the key advantages of the Tapping Machine is its ability to automate the tapping process, reducing the need for manual labor and increasing efficiency. This not only saves time but also minimizes the potential for human error, resulting in higher precision and consistency in the threaded holes created. Additionally, the machine's high-speed tapping capabilities allow for a much faster production pace, ultimately boosting overall productivity and output.Furthermore, the Tapping Machine is designed to be user-friendly, making it accessible to a wide range of operators with varying levels of experience. Its intuitive interface and easy-to-use controls allow for seamless operation, while its robust construction ensures durability and reliability, even in the most demanding manufacturing environments.In addition to its performance capabilities, the Tapping Machine is also equipped with advanced safety features to protect both the operator and the machine itself. With built-in safety protocols and sensors, the machine is designed to minimize the risk of accidents and malfunctions, providing a secure and stable work environment for all involved.As a leading provider of industrial machinery, {} is committed to delivering innovative solutions that meet the evolving needs of modern manufacturing. Their Tapping Machine exemplifies this commitment, offering a comprehensive and effective tool for businesses looking to optimize their tapping operations and stay ahead of the competition.With its cutting-edge technology, superior performance, and user-friendly design, the Tapping Machine from {} has become a game-changer in the manufacturing industry, providing businesses with a powerful tool to enhance their production processes and achieve greater success in today's competitive market.As companies continue to seek ways to improve their manufacturing capabilities, the Tapping Machine stands out as a valuable investment that can drive efficiency, precision, and productivity, ultimately shaping the future of manufacturing as we know it. With its proven track record and innovative features, this machine is poised to continue making a significant impact on the industry, setting a new standard for tapping operations and solidifying its place as a vital component of modern manufacturing processes.

Mastering the Art of Milling with a Drill Press

Milling With A Drill Press: A New Approach to Precision MachiningIn the world of manufacturing, precision is everything. From automotive production to aerospace engineering, success hinges on the ability to quickly and accurately create complex shapes and components. That's why machining has become such a vital part of modern industry—it allows us to create high-quality parts with incredible speed and accuracy.Today, we're excited to introduce a new solution that's poised to revolutionize the world of machining: milling with a drill press. This innovative technique combines the power and precision of a drill press with the flexibility and versatility of a milling machine, making it easier than ever to create complex shapes and structures.At the center of this innovation is our newest product, which we're proud to say is unlike anything else on the market. Featuring cutting-edge technology and precision-designed components, this machine is the perfect way to take your machining processes to the next level. Whether you're a small business owner looking to improve your production capabilities or an established manufacturer looking to expand your operations, this innovative solution has everything you need to succeed.One of the key advantages of milling with a drill press is its flexibility. Unlike traditional milling machines, which are often bulky and difficult to move around, our product is compact, portable, and easy to set up. This means that you can take your machining processes on the go, making it easier than ever to create high-quality parts no matter where you are.But flexibility isn't the only advantage of our milling solution. It's also incredibly precise, thanks to its powerful motor and precision-machined components. With this machine, you can achieve accuracy levels that simply wouldn't be possible with other tools. And because it's designed to work on a range of materials, from metal to wood to plastics, you'll have everything you need to create the perfect components for your business.Of course, no machining solution is complete without the right accessories and support. That's why we offer a full range of milling bits, cutting tools, and other accessories to help you get the most out of your machine. And with our expert technical support team available around the clock, you'll always have the support you need to keep your machining processes running smoothly.Whether you're a seasoned machinist or a newbie just getting started in the industry, milling with a drill press is an exciting new option that's worth exploring. With the right tools and the right approach, you'll be amazed at what you can achieve. So why not take the first step and learn more about this innovative new approach today? We're confident that you'll be glad you did.

New Axis DRO System Revolutionizes Precision Measurement in Manufacturing

One Axis DRO System Revolutionizing Manufacturing IndustryIn the ever-evolving world of manufacturing, companies are constantly seeking new technologies to improve efficiency, accuracy, and productivity. One such innovation that is making waves in the industry is the one axis DRO system. This cutting-edge technology has the potential to revolutionize the manufacturing process and has been gaining popularity among businesses seeking to stay ahead of the competition.The one axis DRO system, developed by {Company}, is a digital readout system that allows for precise and real-time measurement of the position of a single axis on a machine tool. This technology provides operators with unparalleled accuracy and control, leading to improved quality of manufactured components and reduced waste. The DRO system is compatible with a wide range of machine tools, including lathes, milling machines, and grinders, making it a versatile solution for manufacturers across various industries.One of the key features of the one axis DRO system is its user-friendly interface, which allows operators to easily input and track measurements without the need for manual calculations. This not only saves time but also reduces the potential for human error, resulting in more consistent and reliable results. Additionally, the system can store measurement data for future reference, providing valuable insights into the performance of the machine tool and helping identify areas for improvement.{Company} has been a leader in the manufacturing technology industry for over 20 years, with a strong focus on innovation and continuous improvement. The one axis DRO system is a testament to the company's commitment to providing cutting-edge solutions to its customers. With a team of experienced engineers and developers, {Company} has been able to develop and refine the DRO system to meet the specific needs of modern manufacturers.According to {Company} CEO, Steven Smith, "The one axis DRO system represents a significant advancement in manufacturing technology. We believe that this technology has the potential to transform the way businesses operate, allowing for greater precision and efficiency in the production process."The DRO system has already been implemented by several manufacturing companies, with overwhelmingly positive feedback. Many have reported significant improvements in the accuracy of their machining operations, leading to higher quality products and increased customer satisfaction. Some have even seen a reduction in production costs due to decreased waste and rework.As the manufacturing industry continues to evolve, the demand for advanced technologies like the one axis DRO system is expected to grow. With its potential to streamline operations and improve overall productivity, many businesses are recognizing the value of investing in this innovative solution. In the current competitive landscape, having the latest technology can provide a crucial edge for companies looking to stay ahead of the curve.Looking ahead, {Company} is committed to further advancing the capabilities of the one axis DRO system, with plans to integrate additional features and functionalities based on customer feedback and industry trends. The company also aims to expand its reach to new markets, bringing the benefits of this technology to a wider audience of manufacturers.In conclusion, the one axis DRO system developed by {Company} is a game-changer for the manufacturing industry. With its unparalleled accuracy, ease of use, and potential for cost savings, this technology is poised to revolutionize the way companies approach their machining operations. As businesses continue to seek ways to stay competitive, the demand for advanced solutions like the one axis DRO system is only set to increase, making it a crucial investment for the future of manufacturing.

Milling Machine Clamping Kit: Everything You Need to Know

Milling Machine Clamping Kit is an essential tool for any machining operation. Whether you are a professional machinist or a hobbyist, having the right clamping kit can make all the difference in the efficiency and precision of your work. One company that has been providing high-quality clamping kits for milling machines is {Company Name}.{Company Name} has been a leading provider of machining tools and accessories for over 20 years. With a strong focus on quality and customer satisfaction, they have earned a reputation for being a reliable source for all machining needs. Their wide range of products includes cutting tools, measuring instruments, and of course, clamping kits for milling machines.The milling machine clamping kits offered by {Company Name} are designed to provide a secure and stable grip on workpieces of all shapes and sizes. These kits come with a variety of clamping components such as T-slot nuts, flange nuts, step clamps, and studs, all made from high-quality materials to ensure durability and precision. Whether you are working on a small DIY project or a large-scale industrial job, {Company Name} has the right clamping kit to meet your needs.One of the key advantages of {Company Name}'s milling machine clamping kits is their versatility. These kits are compatible with a wide range of milling machines, making them a practical choice for machinists with diverse machining needs. The company also offers customization options for their clamping kits, allowing customers to tailor the kits to their specific requirements.In addition to the quality of their products, {Company Name} is also known for their exceptional customer service. The company's team of knowledgeable and experienced staff are always available to provide expert advice and assistance, ensuring that customers find the right clamping kit for their needs. With a commitment to customer satisfaction, {Company Name} has built long-lasting relationships with clients in various industries.As technology continues to advance in the machining industry, {Company Name} remains at the forefront by continuously updating and improving their product line. They stay abreast of the latest trends and innovations in machining to ensure that their clamping kits are up to date and meet the demands of modern machining operations. This dedication to staying ahead of the curve has made {Company Name} a trusted name in the industry.Another key aspect of {Company Name}'s success is their commitment to quality control. All of their milling machine clamping kits undergo rigorous testing and inspection to ensure that they meet the highest standards of performance and reliability. This attention to detail has earned {Company Name} a reputation for delivering products that offer exceptional value and longevity.In conclusion, {Company Name} is a reputable and reliable provider of milling machine clamping kits. With a focus on quality, versatility, and customer satisfaction, the company has established itself as a go-to source for machining tools and accessories. Whether you are a seasoned professional machinist or a hobbyist, {Company Name} has the expertise and products to meet your machining needs. Their commitment to innovation and customer service sets them apart in the industry and makes them a dependable partner for all machining projects.

High-Quality 25m Wire Feeder for Welding Applications

The Lincoln 25m Wire Feeder is a cutting-edge piece of industrial equipment that has been making waves in the manufacturing and welding industries since its launch. This state-of-the-art wire feeder is designed to provide exceptional performance and reliability, making it an indispensable tool for businesses of all sizes.The wire feeder is manufactured by a leading company in the welding industry, which has been a pioneer in developing innovative welding solutions for over 100 years. With a strong focus on research and development, the company has consistently delivered top-tier products that meet the demands of modern-day manufacturing and fabrication processes.The Lincoln 25m Wire Feeder is a testament to the company's commitment to excellence. It is equipped with advanced features that allow for seamless wire feeding, ensuring consistent and precise welds every time. The feeder is also designed to be highly user-friendly, with intuitive controls and a straightforward setup process, making it accessible to welders of all skill levels.One of the standout features of the wire feeder is its robust construction, which is designed to withstand the rigors of industrial work environments. This ensures that the feeder can endure heavy use and harsh conditions without compromising its performance, making it a reliable and long-lasting investment for businesses.In addition to its durability, the wire feeder is also equipped with advanced technology that enhances its efficiency and productivity. This includes features such as a digital display that provides real-time feedback on wire speed and voltage, as well as programmable settings that allow for customized welding parameters to be saved and easily accessed.The company behind the Lincoln 25m Wire Feeder is dedicated to providing comprehensive support to its customers. This includes offering extensive training and technical support to ensure that businesses can maximize the potential of the wire feeder and achieve the best possible results in their welding processes.Furthermore, the company's commitment to sustainability is reflected in the design and manufacturing of the wire feeder. With a focus on energy efficiency and minimizing environmental impact, the feeder is in line with the company's dedication to responsible and eco-friendly practices in all aspects of its operations.The Lincoln 25m Wire Feeder has already garnered widespread acclaim within the industry, with businesses praising its reliability, performance, and user-friendly design. Many have reported significant improvements in their welding processes and overall productivity since incorporating the wire feeder into their operations.Looking ahead, the company continues to push the boundaries of innovation with ongoing research and development efforts aimed at further enhancing the capabilities of the wire feeder. With a steadfast commitment to meeting the evolving needs of the manufacturing and welding industries, the company is well-positioned to remain a leader in delivering high-quality solutions like the Lincoln 25m Wire Feeder.In conclusion, the Lincoln 25m Wire Feeder represents a game-changing advancement in the field of welding technology. With its unparalleled performance, reliability, and user-friendly design, it has quickly become an essential tool for businesses looking to elevate their welding processes. Backed by a company with a rich history of innovation and a dedication to excellence, the wire feeder is poised to continue making a significant impact in the industry for years to come.

High-powered grinder for heavy-duty projects

Power Max Grinder Revolutionizes the Industry with Cutting-Edge TechnologyThe Power Max Grinder has taken the power tool industry by storm with its revolutionary design and cutting-edge technology. Developed and brought to market by a leading manufacturer in the industry, the Power Max Grinder has quickly become the go-to choice for professionals and DIY enthusiasts alike.With its powerful motor and advanced features, the Power Max Grinder sets a new standard for performance and reliability. Whether it's grinding, cutting, or polishing, this versatile tool delivers exceptional results every time. The grinder's ergonomic design and comfortable grip make it easy to handle, even during long and demanding jobs.One of the key features of the Power Max Grinder is its innovative cooling system, which ensures that the motor stays at an optimal temperature, even during prolonged use. This not only extends the life of the tool but also ensures consistent performance. In addition, the grinder's quick-change system allows for easy and efficient accessory changes, saving time and increasing productivity.Furthermore, the Power Max Grinder is equipped with advanced safety features, including a kickback brake and a vibration control system, providing users with added peace of mind while working with this powerful tool. These safety features, combined with the grinder's durability and reliability, make it an ideal choice for professionals who rely on their tools day in and day out.In addition to its impressive performance, the Power Max Grinder is backed by the manufacturer's commitment to quality and customer satisfaction. The company has a long-standing reputation for producing top-of-the-line power tools, and the Power Max Grinder is no exception. With a focus on innovation and continuous improvement, the company is dedicated to providing its customers with the best tools available on the market.Furthermore, the manufacturer offers a comprehensive warranty and customer support, ensuring that users can rely on their Power Max Grinder for years to come. This level of commitment to quality and customer service has helped the company build a loyal customer base and establish itself as a leader in the power tool industry.The Power Max Grinder has already received praise and recognition from industry professionals and experts. Its innovative design and advanced features have set a new standard for power tools, and it has quickly become a bestseller in the market. With its exceptional performance and reliability, the Power Max Grinder is bringing a new level of efficiency and precision to the industry.The Power Max Grinder is not only a game-changer for professionals but also a valuable addition to any DIY enthusiast's toolkit. Whether it's tackling a home renovation project or working on a creative endeavor, the Power Max Grinder provides the power and versatility needed to get the job done right.In conclusion, the Power Max Grinder has redefined what users can expect from a power tool. With its powerful motor, advanced features, and commitment to quality, this grinder has set a new standard for performance and reliability. Backed by a leading manufacturer in the industry, the Power Max Grinder is already making a significant impact and is poised to continue revolutionizing the industry for years to come.

High-Precision Jacobs Type Chuck for Accessories Ranging from .001mm to 6.4mm

release:Precision Chuck Introduction: The Ultimate Solution for Your Industrial NeedsAre you in the manufacturing sector and seeking a reliable and efficient chuck to enhance your production process? Look no further than the Precision Chuck. Our product is a precise Jacobs type chuck for use with chuck accessories having a diameter of .001 [0.03mm] to .250 [6.4mm]. With its unmatched precision and quality, the Precision Chuck is the ultimate solution for your industrial needs.Designed for Maximum EfficiencyThe Precision Chuck is designed to help you achieve maximum efficiency in your industrial processes. With its high-quality construction and precision engineering, it provides a secure hold on your workpieces, ensuring a smooth and stable production process. This chuck is highly versatile and can be used with a wide range of products, making it a valuable addition to any industrial setup.Made from Durable MaterialsAt the Precision Chuck, we understand that your industrial processes rely on tools that are tough, durable, and reliable. Our Precision Chucks are manufactured with this in mind, using only top-grade materials that can withstand even the most demanding applications. The chucks are crafted with precision and are built to last for years without showing any signs of wear and tear.Efficient and ReliableThe Precision Chuck is the ultimate solution for your industrial needs because it is both efficient and reliable. This chuck saves you time, reduces waste, and enhances your overall productivity by ensuring that your workpieces remain securely held in place throughout your production process. Its unmatched accuracy and precision make it an essential tool for any industrial manufacturer.Customizable OptionsAt the Precision Chuck, we understand that different industrial applications have varying needs. That’s why we offer customizable options that let you choose the best solution for your unique manufacturing requirements. Whether you need a different size chuck or want a specific type of chuck accessory, we’re here to help.Exceptional Customer SupportAt the Precision Chuck, we’re committed to providing exceptional customer support. We’re always available to answer any questions you have, and our experienced technicians are on hand to help you with all your chuck needs. We offer comprehensive support throughout the buying process, making it easy for you to select the best product for your industrial application.About UsThe Precision Chuck is a product of our company, a leading manufacturer of industrial chucks and accessories. With over years of experience in the industry, we have built a reputation for excellence in our products and services. Our team of engineers and technicians is dedicated to providing innovative solutions that enhance the productivity of industrial manufacturers.ConclusionAt the Precision Chuck, we take pride in offering our customers the best possible products for their industrial needs. Our Precision Chucks are the ultimate solution for manufacturers looking to enhance their productivity and reliability. With customizable options, exceptional customer support, and precision engineering, our chucks are the perfect tool for any industrial setup. Contact us today to learn more about how our Precision Chucks can benefit your manufacturing processes.

Top Quality Live Centers for Precision Machinery

Live Center Chuck Introduces Groundbreaking Innovation in Industrial Lathe MachineryLive Center Chuck, a leading provider of industrial lathe machinery solutions, has introduced a groundbreaking innovation that is set to revolutionize the industry. With over 20 years of experience in the field, Live Center Chuck has continually pushed the boundaries of technology to deliver cutting-edge solutions to its clients.The new innovation, which comes in the form of a state-of-the-art live center chuck, is designed to significantly improve the efficiency and precision of lathe machinery operations. This development marks a major milestone for the company as it solidifies its position as a pioneer in the industry.Live Center Chuck has always prided itself on its ability to stay ahead of the curve by anticipating the evolving needs of its customers. The introduction of this new innovation is a testament to the company's unwavering commitment to innovation and excellence.The live center chuck is equipped with advanced features that enhance its performance and reliability. Its precision design ensures that it can accommodate a wide range of workpieces with varying sizes and materials. This versatility makes it an invaluable tool for manufacturers across different sectors.Furthermore, the live center chuck boasts enhanced durability and longevity, thanks to its robust construction and high-quality materials. This ensures that it can withstand the rigors of heavy-duty industrial applications, delivering consistent performance over an extended period.One of the key benefits of the new live center chuck is its ability to improve the overall productivity of lathe machinery operations. Its advanced design minimizes setup times and allows for faster and more efficient machining processes. This directly translates to increased throughput and cost savings for businesses.In addition to its productivity enhancements, the live center chuck also contributes to the improvement of the quality of finished products. Its precise positioning and reliable gripping mechanism enable operators to achieve finer tolerances and superior surface finishes, meeting the strictest quality standards.The introduction of this innovation has already generated significant interest and excitement within the industry. Customers are eager to experience the transformative impact that the new live center chuck can have on their operations. With its promise of increased efficiency and superior performance, it is set to become an essential component of modern lathe machinery systems.Live Center Chuck's commitment to customer satisfaction extends beyond the product itself. The company has established a comprehensive support system to ensure that its clients can maximize the benefits of the new live center chuck. This includes technical assistance, training, and maintenance services, all aimed at empowering businesses to fully leverage the potential of the innovation.As Live Center Chuck continues to push the boundaries of what is possible in industrial lathe machinery, it is clear that the company is poised for even greater success in the future. Its dedication to innovation and excellence has cemented its reputation as a trusted partner for businesses seeking to elevate their manufacturing capabilities.In conclusion, the introduction of the groundbreaking live center chuck represents a significant leap forward in the evolution of industrial lathe machinery. With its unparalleled performance, versatility, and reliability, it is set to redefine the standards of excellence in the industry. Live Center Chuck remains at the forefront of technological innovation, and its new innovation is a testament to its unwavering commitment to driving progress and success for its clients.

Discover the Advantages of Using a Spindle Moulder Power Feed for Woodworking Projects

Introducing New Spindle Moulder Power Feed: Revolutionizing Woodworking Industry[Company Name], a leading provider of woodworking machinery and equipment, has recently unveiled its latest innovation in the woodworking industry – the new Spindle Moulder Power Feed. This groundbreaking product is set to revolutionize the way woodworkers operate their spindle moulders, offering increased efficiency, precision, and safety features that are unmatched in the industry.With over [X] years of experience in designing and manufacturing high-quality woodworking machinery, [Company Name] has established itself as a trusted brand in the woodworking industry. The company is known for its commitment to innovation and customer satisfaction, and the introduction of the Spindle Moulder Power Feed is a testament to this dedication.The Spindle Moulder Power Feed is designed to enhance productivity and accuracy in woodworking operations. Equipped with advanced features such as variable speed control, automated feeding, and adjustable settings, this powerful tool provides woodworkers with the ability to produce high-quality, precision-cut mouldings with ease. The power feed mechanism allows for smooth and consistent feeding of the workpiece through the moulder, reducing the risk of sniping and tear-out while ensuring a uniform finish.In addition to its cutting-edge technology, the Spindle Moulder Power Feed prioritizes safety in its design. The integrated safety features include an emergency stop button, overload protection, and a safety guard to prevent any potential accidents or injuries during operation. This ensures that woodworkers can operate the machine with peace of mind, knowing that their safety is paramount."We are thrilled to introduce the new Spindle Moulder Power Feed to the woodworking industry," said [Spokesperson Name], CEO of [Company Name]. "This product is the result of our commitment to innovation and our dedication to providing woodworkers with the tools they need to succeed. We believe that the Spindle Moulder Power Feed will significantly improve the efficiency and precision of woodworking operations, while also prioritizing the safety of our customers."The Spindle Moulder Power Feed is suitable for a wide range of woodworking applications, from small-scale woodworking shops to large industrial woodworking facilities. Its versatility and ease of use make it an ideal addition to any woodworking operation, enabling woodworkers to achieve consistent, high-quality results with minimal effort.To ensure customer satisfaction, [Company Name] offers comprehensive technical support and training for the Spindle Moulder Power Feed. Their team of experienced technicians is available to assist customers with installation, operation, and maintenance of the product, ensuring that woodworkers can maximize its potential and longevity.In conclusion, the introduction of the Spindle Moulder Power Feed marks a significant milestone for the woodworking industry. With its advanced technology, safety features, and commitment to customer satisfaction, [Company Name] has once again demonstrated its leadership in the woodworking machinery market. Woodworkers can now experience a new level of efficiency, precision, and safety with the Spindle Moulder Power Feed, solidifying its position as a game-changer in the woodworking industry.

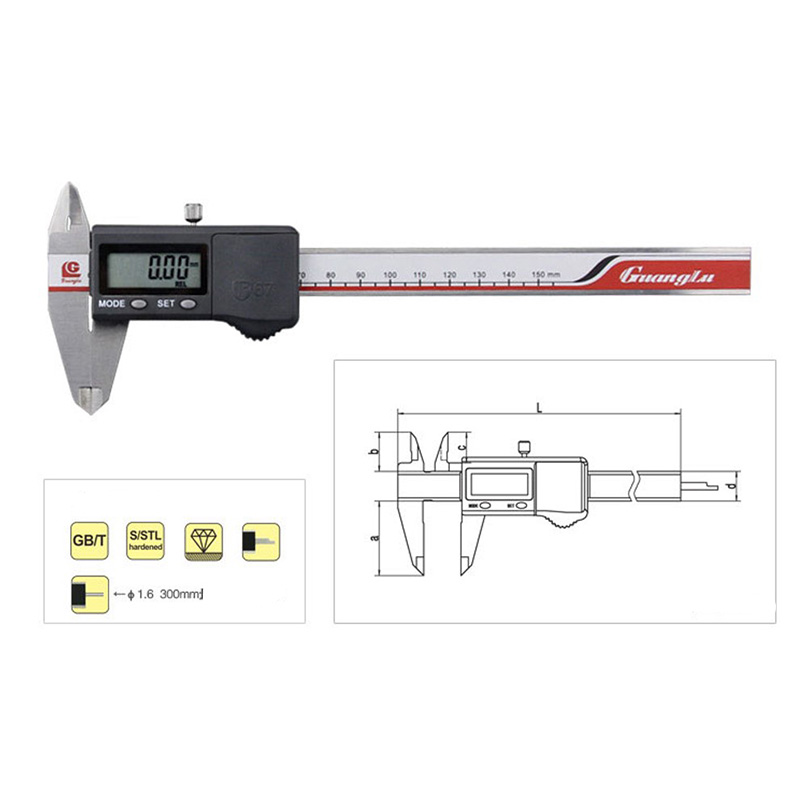

Precision Metal Casing Digital Caliper for Accurate Measurements

Precision Measurement Company introduces the new Metal Casing Digital Caliper to the market, offering an innovative and reliable solution for accurate measurements. The caliper is designed to meet the needs of professionals and hobbyists who require precision and durability in their measuring tools.The Metal Casing Digital Caliper is equipped with a high-quality metal casing that provides excellent protection for the internal components, ensuring long-term reliability and accuracy. The durable construction makes it suitable for use in various environments, including workshops, laboratories, and industrial settings.One of the standout features of the Metal Casing Digital Caliper is its high-resolution digital display, which allows for easy and precise reading of measurements. The large and clear display ensures that users can quickly and accurately read the values, eliminating any potential for human error in data interpretation.In addition to its robust construction and user-friendly display, the Metal Casing Digital Caliper also boasts a range of advanced features that set it apart from other calipers on the market. These include a smooth gliding mechanism for precise sliding and an easy-to-use locking screw for securing measurements in place.Furthermore, the caliper is equipped with an integrated depth gauge for measuring depth and step dimensions, as well as an inside and outside diameter measurement capability for versatile applications. This makes it a versatile and indispensable tool for a wide range of measurement tasks.The Metal Casing Digital Caliper is also designed with user comfort in mind, featuring an ergonomic design that allows for prolonged use without causing discomfort or fatigue. The smooth and efficient operation of the caliper ensures that measurements can be taken quickly and accurately, making it a valuable asset for professionals who require efficiency and precision in their work.As a leading provider of precision measurement tools, Precision Measurement Company has a long-standing reputation for delivering high-quality and reliable products to its customers. With the introduction of the Metal Casing Digital Caliper, the company reaffirms its commitment to providing innovative solutions that meet the evolving needs of its customers."We are proud to introduce the Metal Casing Digital Caliper to the market," said a spokesperson for Precision Measurement Company. "This caliper represents the culmination of our dedication to developing tools that offer exceptional performance, durability, and ease of use. We are confident that it will meet the needs of professionals and hobbyists alike, and we are excited to see the positive impact it will have in various industries."The Metal Casing Digital Caliper is now available for purchase through authorized distributors and retailers. Its introduction to the market is set to revolutionize the way professionals and hobbyists approach precision measurements, providing a reliable and efficient tool that delivers accurate results time and time again. With its durable construction, advanced features, and user-friendly design, the caliper is poised to become an indispensable asset in a wide range of industries.